General usage information for PyroSim

There is a newer version of this document. To view the latest version, click here.

Thunderhead Engineering makes no warranty, expressed or implied, to users of PyroSim, and accepts no responsibility for its use. Users of PyroSim assume sole responsibility under Federal law for determining the appropriateness of its use in any particular application, for any conclusions drawn from the results of its use, and for any actions taken or not taken as a result of analyses performed using these tools.

Users are warned that PyroSim is intended for use only by those competent in the fields of fluid dynamics, thermodynamics, combustion, and heat transfer, and is intended only to supplement the informed judgment of the qualified user.

The software package is a computer model that may or may not have predictive capability when applied to a specific set of factual circumstances. Lack of accurate predictions by the model could lead to erroneous conclusions with regard to fire safety. All results should be evaluated by an informed user.

All other product or company names that are mentioned in this publication are tradenames, trademarks, or registered trademarks of their respective owners.

Throughout this document, the mention of computer hardware or commercial software does not constitute endorsement by Thunderhead Engineering, nor does it indicate that the products are necessarily those best suited for the intended purpose.

We thank Kevin McGrattan, Simo Hostikka, Randall McDermott, Jason Floyd, Craig Weinschenk, Kristopher Overholt, and Glenn Forney in the Building and Fire Research Laboratory at the National Institute of Standards and Technology and the VTT Technical Research Centre of Finland. They are the primary authors of the Fire Dynamics Simulator and Smokeview, without which PyroSim would not exist. They have been gracious in their responses to our many questions.

We would like to gratefully acknowledge the RJA Group for their collaboration with Thunderhead engineering in the development of PyroSim. Feedback and testing from the engineers at RJA has improved the usability and quality of PyroSim.

Development of PyroSim was originally supported by the National Science Foundation under Grants DMI-0232401 and DMI-0349759. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

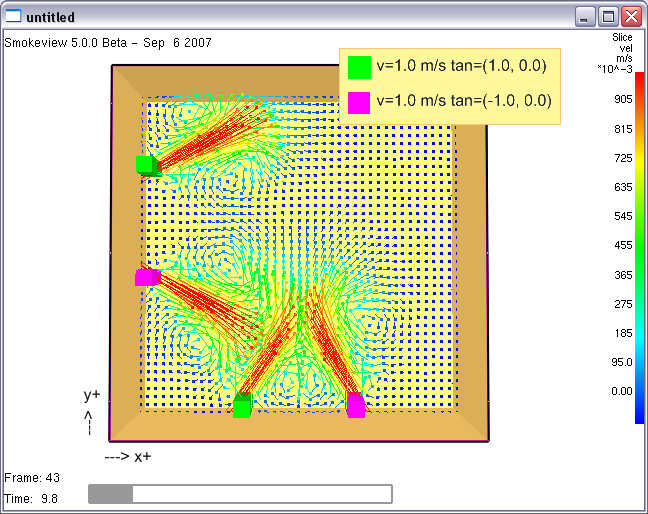

PyroSim is a graphical user interface for the Fire Dynamics Simulator (FDS) version 6.7.4. FDS is closely integrated into PyroSim. FDS models can predict smoke, temperature, carbon monoxide, and other substances during fires. The results of these simulations are used to ensure the safety of buildings before construction, evaluate safety options of existing buildings, reconstruct fires for post-accident investigation, and assist in firefighter training.

FDS is a powerful fire simulator which was developed at the National Institute of Standards and Technology (NIST). FDS simulates fire scenarios using computational fluid dynamics (CFD) optimized for low-speed, thermally-driven flow. This approach is very flexible and can be applied to fires ranging from stove-tops to oil storage tanks. It can also model situations that do not include a fire, such as ventilation in buildings.

The PyroSim interface provides immediate input feedback and ensures the correct format for the FDS input file.

Some highlights include:

In summary, PyroSim helps you quickly and reliably build complex fire models.

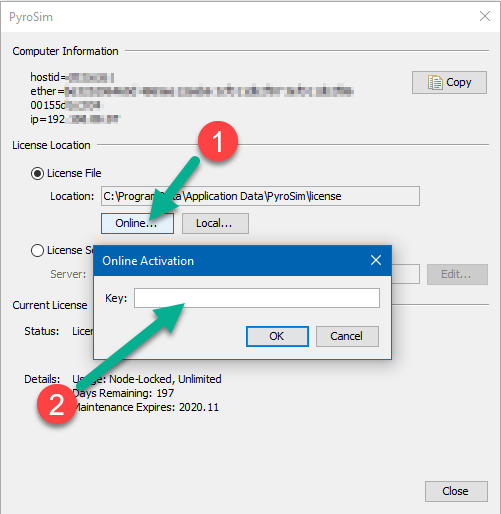

You can download the current version, sign up for a free trial, and purchase the software from the PyroSim Support Page. This page also provides instructions for installation and activation. Troubleshooting info can be found on the PyroSim FAQs page. There is no functional difference between the trial version of PyroSim and the full version, the only limitation is the trial license duration.

When installing PyroSim, the installer will either upgrade an existing version or install PyroSim to a new location, this behavior is based on the version. In the case of minor updates (e.g. upgrading from PyroSim 2020.1 to PyroSim 2020.2), the installer will remove the older version and replace it with the new version. When installing a major update (e.g. PyroSim 2019 to PyroSim 2020), the older version will not be modified and the newer version will be installed to a different folder.

Administrator privileges are required to install PyroSim. This is necessary because the installer adds processes to the operating system for license management and parallel FDS simulation.

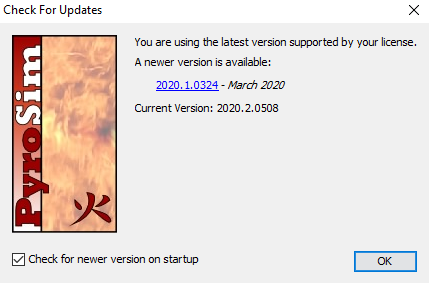

PyroSim will regularly check for and notify the user of available updates to the software when configured to do so. By default, PyroSim will check for updates on startup and display the relevant information in the Check For Updates dialog when one is available.

Users can also access this dialog by navigating to Help→Check For Updates

The dialog can be disabled on startup by unchecking Check for newer version on startup.

In this section we make some suggestions that can help speed your model development. The big issues most users will face are: selecting a mesh, defining your geometry, selecting a reaction, and defining the correct boundary conditions.

We will broadly discuss each of those topics, but before you start thinking about them please:

The analyst will always need to balance solution time and accuracy. Reducing the mesh size by a factor of 2, will result in approximately a factor of 16 more computation time (a factor of 8 due to the number of cells and an additional factor of 2 due to reduced step size).

Two criteria will control the applicable mesh size:

For fire plumes, an initial mesh size estimate can be obtained as a fraction of the characteristic fire diameter (D*), see Materials of the Fire Dynamics Simulator Technical Reference Guide Volume 3: Validation. You can download a D* calculator from the PyroSim Resources page. Initial calculations should be done with a coarse mesh (\(\frac{D^{*}}{5}\)), but a mesh size study must be employed to analyze the suitability of the mesh (\(\frac{D^{*}}{20}\)).

An example of a convergence study for jet fans (no fire) can be found in the series of posts Modeling Jet Fans found on the PyroSim Tutorials web page. Here the solution was compared with experimental data.

In some problems the mesh resolution must be selected to adequately represent the geometry. An example where geometry controlled the mesh size is the modeling of a wood crib where each stick had a small diameter (see Modeling Fire, Part 4 - Combustion with HRR, Ignition, and Burn Away on the Thunderhead website).

By default, no reaction is specified, a reaction is only needed if there will be a fire in the simulation. In FDS, a reaction defines not only the fuel and the products but also the Heat of Combustion. Once the heat of combustion and the desired HRR is known, FDS calculates the fuel mass flow rate from the surface.

For most situations, it is sufficient to use the "Simple Chemistry" model, where a single fuel species is composed of \(C\), \(H\), \(O\), and \(N\) that reacts with oxygen (\(Air\)) to form the product species consisting of \(H_{2}O\), \(CO_{2}\), \(Soot\), \(N_{2}\), and \(CO\). The user specifies the chemical formula of the fuel along with the yields of \(CO\) and \(Soot\), and the volume fraction of hydrogen in the \(Soot\), \(X_{H}\). A limited number of reactions are included in FDS and can be added from the library.

See Chapter 12 of the FDS User Guide for a more detailed discussion of combustion. The PyroSim Resources page provides Combustion and Fuel Composition calculators.

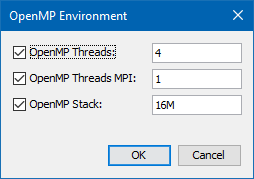

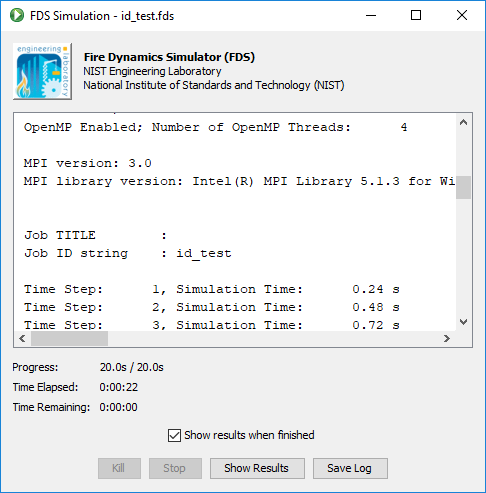

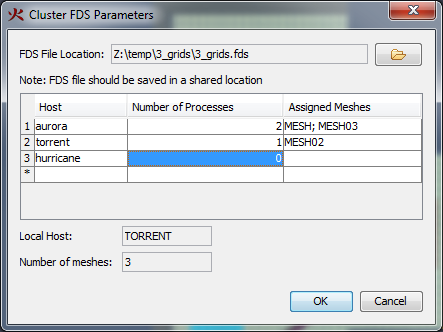

Parallel processing can speed the solution. In general, our experience indicates that running on multiple cores on the same computer offers the most significant improvement. Using multiple computers in a cluster can make it possible to solve larger problems, but the communication delays between computers tend to cancel the speed improvement of parallel processing.

The good news is that that standard installation of PyroSim includes support for parallel processing on the same computer. All the user must do is define multiple meshes and then select Run FDS Parallel.

PyroSim includes tools to manage multiple meshes. One effective strategy is to first define a single mesh that spans the entire model. Then use the PyroSim mesh splitting tool to create multiple meshes. You can then change the resolution of selected meshes using the Refine Mesh option and all the meshes will automatically stay correctly aligned.

All geometry in FDS is defined at the mesh resolution. Even if you input the geometry of an obstruction or vent to lie between cell corner points, when FDS runs the solution, all the geometry will be "snapped" to the grid.

If you are drawing your own geometry in PyroSim, you can select the Snap to Model Grids option that will ensure that your geometry matches the grid. You can also ensure that objects will fill entire grid cells rather than a cell face by turning on the Thicken option in the obstruction properties, see Creating Obstructions.

In our experience, numerical instabilities that may occur during the solution are the result of an error in the model, not an error in FDS. The numerical instability typically arises due to either a pressure increase (or decrease) in a mesh. If you see this error, add a pressure sensor to your model and see what is happening to the pressures. Problems typically occur because of how boundary conditions have been defined.

Some common problems with boundary conditions include:

Each PyroSim release comes bundled with FDS. A particular PyroSim release is designed and tested against the bundled version of FDS. You can use PyroSim to run any version of FDS, however PyroSim will generate the input file based on the bundled version of FDS and it is important to understand differences in input format between the FDS versions before changing PyroSim’s FDS version.

To change the version of FDS used by PyroSim:

In preparing this manual, we have liberally used descriptions from the FDS User’s Guide (McGrattan, et al., 2015). Links to the FDS Users Guide, the FDS Technical Reference, and the Smokeview Users Guide are included in PyroSim on the Help menu. You can also download documentation, executables, and verification and validation examples at: https://pages.nist.gov/fds-smv/ .

Thunderhead Engineering

403 Poyntz Avenue, Suite B

Manhattan, KS 66502-6081

USA

Sales Information: sales@thunderheadeng.com

Product Support: support@thunderheadeng.com

Phone: +1.785.770.8511

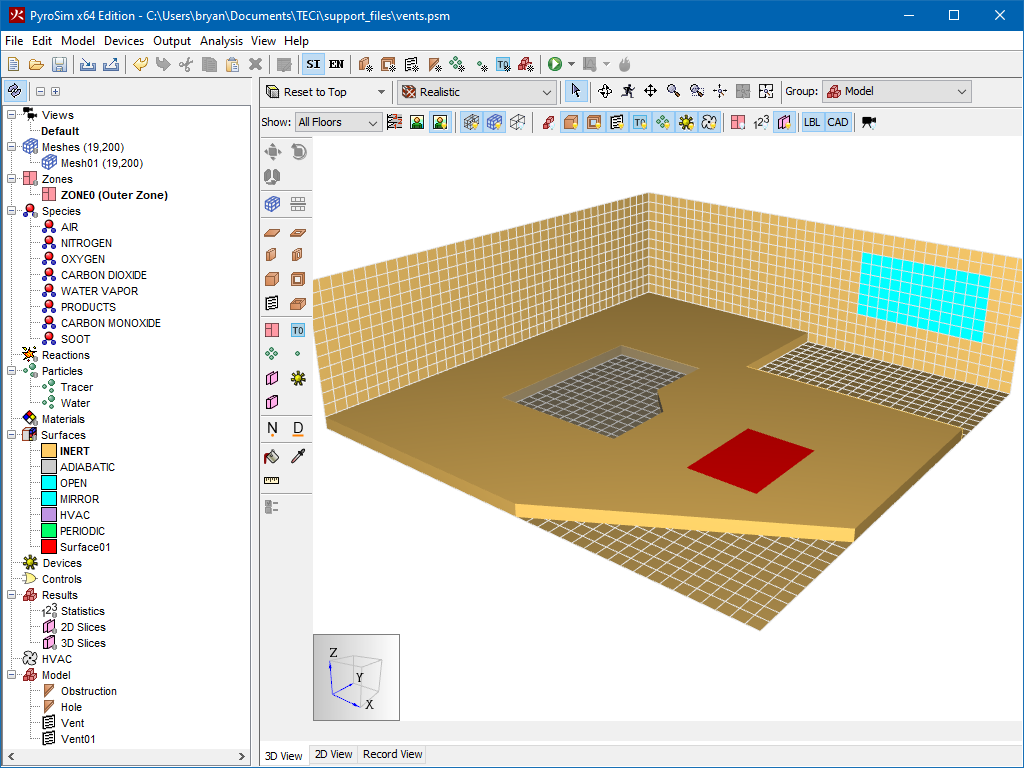

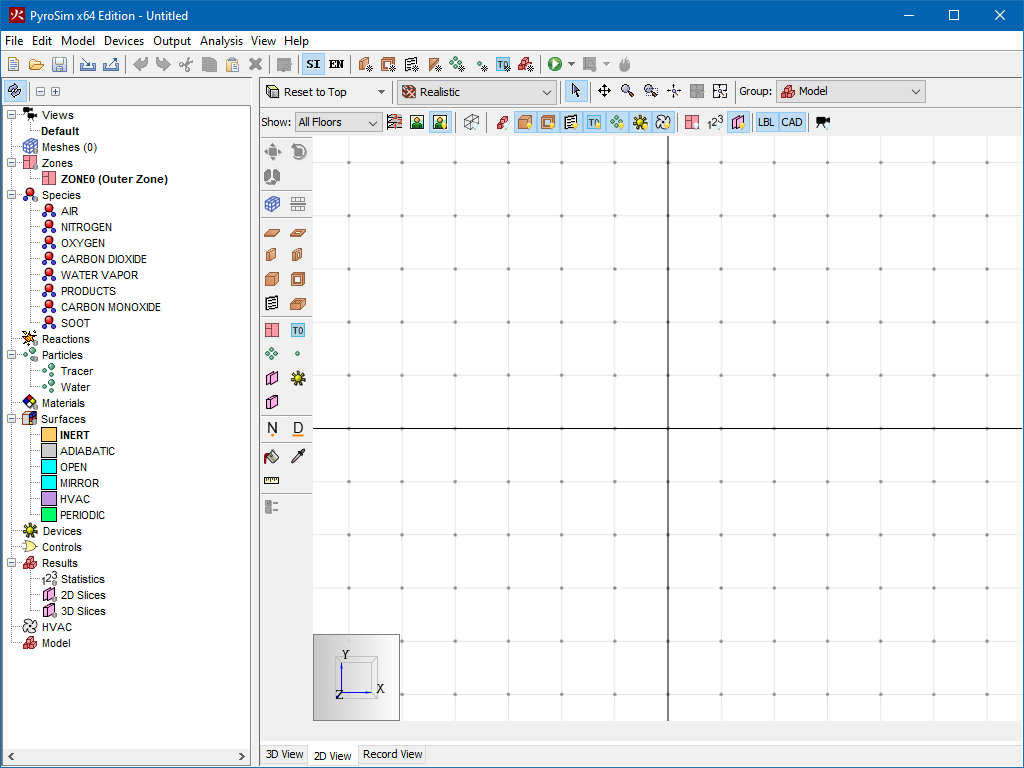

PyroSim provides four editors for your fire model: the 3D View, 2D View, Navigation View, and the Record View. These all represent your current model. If an object is added, removed, or selected in one view, the other views will simultaneously reflect the change.

Each view is briefly described below.

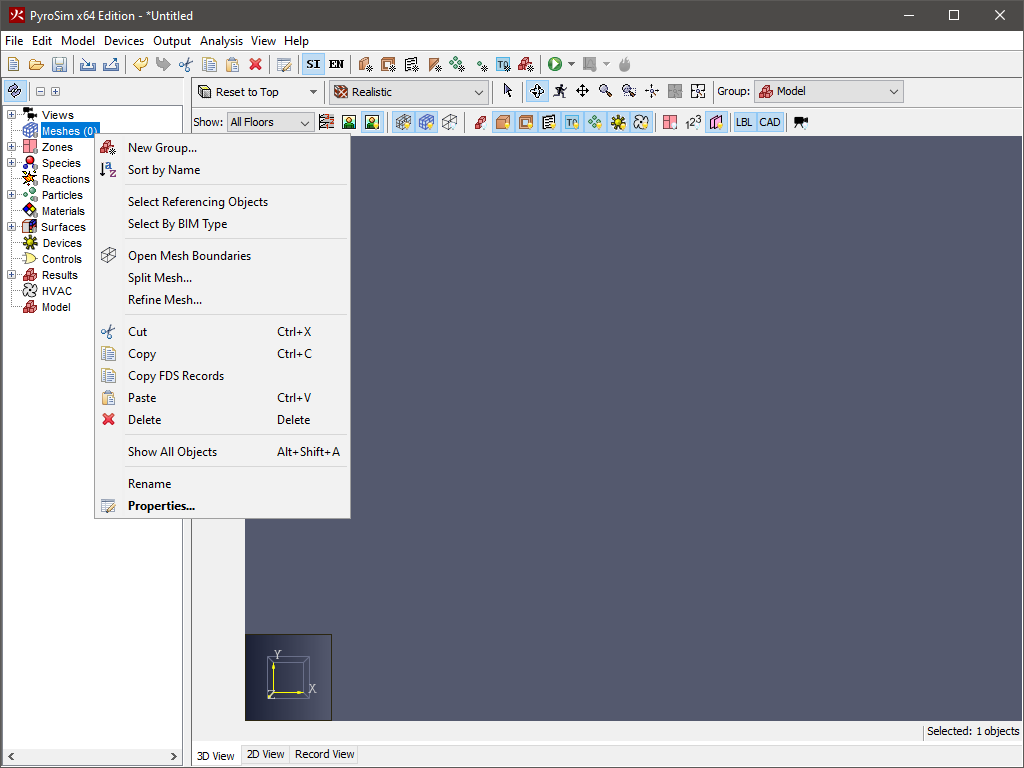

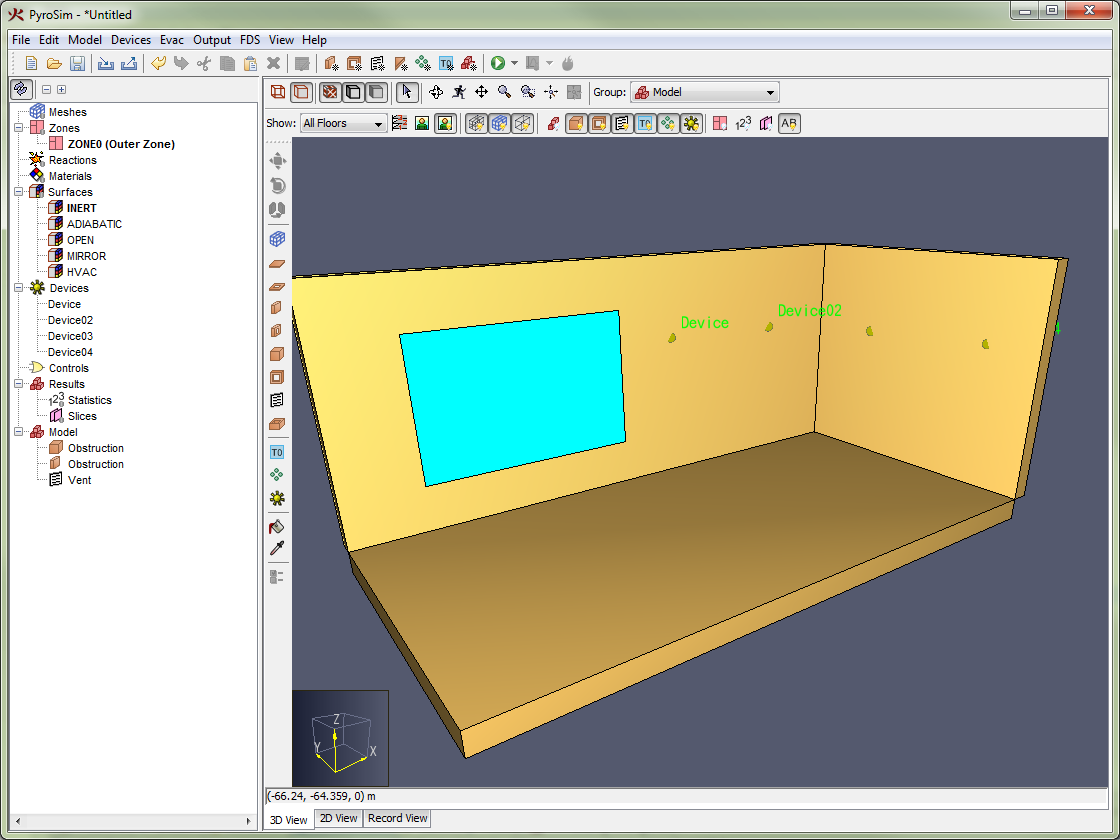

The navigation view is a tree-like view on the left side of the PyroSim main window. An example of this view in use is shown in Figure 2. When you right-click on an item in this view, a list of the functions PyroSim can perform on that item is shown. To rearrange objects in the Navigation view, make a selection and then drag the object(s) to the new location.

Use the 3D view to rapidly obtain a visual image of the model and perform some drafting. In this view, the user can navigate through the model in 3D and select objects. This view also provides display filters to quickly show/hide entire categories of objects or switch between floors. In addition, any drafting that requires objects to be snapped to faces of other objects, such as drawing a vent on an obstruction or attaching a measuring device to a solid can be easily achieved in this view. For more information on drafting, see Drawing in PyroSim.

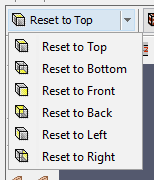

The traditional orthographic views are pre-programmed into PyroSim and are valid in both the 3D and 2D views. It is also possible to save custom camera views, for more information, see Views.

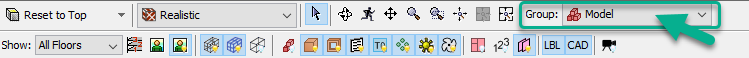

To change the camera view, select the desired view in the drop-down menu, as shown in Figure 3 or press the appropriate hotkey from Table 1.

| View | Hotkey |

|---|---|

| Front | CTRL+1 |

| Back | CTRL+2 |

| Left | CTRL+3 |

| Right | CTRL+4 |

| Top | CTRL+5 |

| Bottom | CTRL+6 |

The drop-down menu is also a clickable button that will reset to the most recent view.

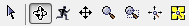

There are several tools that can be used to navigate the model and select objects. The tools for the 3D view are found in the navigation toolbar above the 3D view as shown in Figure 4.

The model can also be zoomed in and out with any of the navigation tools by using the scroll wheel. Scrolling up zooms in and scrolling down zooms out. With all but the Roam Tool, using the scroll wheel will zoom in on the point under the cursor. With the Roam Tool, the scroll wheel only zooms the center of the view.

At any time, the camera’s view can be reset to see the entire extents of the model by clicking the Reset View button (![]() ) or pressing CTRL+r.

In addition, the camera can be reset to only the currently selected objects by clicking the Reset to Visible button (

) or pressing CTRL+r.

In addition, the camera can be reset to only the currently selected objects by clicking the Reset to Visible button (![]() ) or pressing CTRL+e.

Resetting the view also has the effect of changing the orbit center when orbiting.

) or pressing CTRL+e.

Resetting the view also has the effect of changing the orbit center when orbiting.

Orbiting is the action of spinning the camera about its focal point, which is the center of the model or center of the selection, depending on which reset action was last performed. By default, orbit works as if there is an invisible sphere around the model on which you click and drag the mouse to spin. Alternatively, orbiting can be performed similarly to Smokeview by going to the View menu and selecting, Use Smokeview-like Navigation. In this mode the camera spins about the Z axis with left and right mouse movements and about the local X axis with up and down movements.

There are several ways to filter the objects shown in the 3D view. Filtering can be performed with clipping planes that are associated with floors or through filter buttons that can quickly show/hide categories of objects.

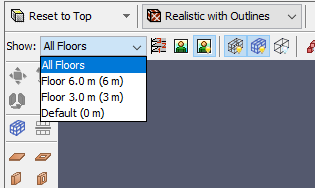

To use clipping, the user must first define floors for the model as discussed in Floors. Once the floors are defined, a floor can be selected by using the Floor Drop-down above the 3D or 2D view as shown in Figure 7.

Once a floor has been selected, its clipping planes will be applied to the entire scene to only show objects within the clipping region.

Filtering can also be performed using the filter toolbar buttons as shown in Figure 8. Selecting/deselecting these buttons will quickly show/hide all objects of a specific type, such as obstructions, holes, vents, etc.

Filtering can also be applied to meshes but in a slightly different way. Instead of showing/hiding all meshes, the user can selectively show/hide three different elements of them using the mesh filter toolbar shown in Figure 9. This toolbar selectively allows viewing mesh grid lines, mesh boundaries, and mesh outlines. Filtering mesh elements shows the different mesh elements. Figure 10 shows the grid lines, Figure 11 shows the boundary, and Figure 12 shows the outline.

Background images attached to floors can be quickly shown/hidden using the Show Background Image filter button (![]() ) next to the floor drop-down.

) next to the floor drop-down.

The 2D view is mostly the same as the 3D view with some key differences:

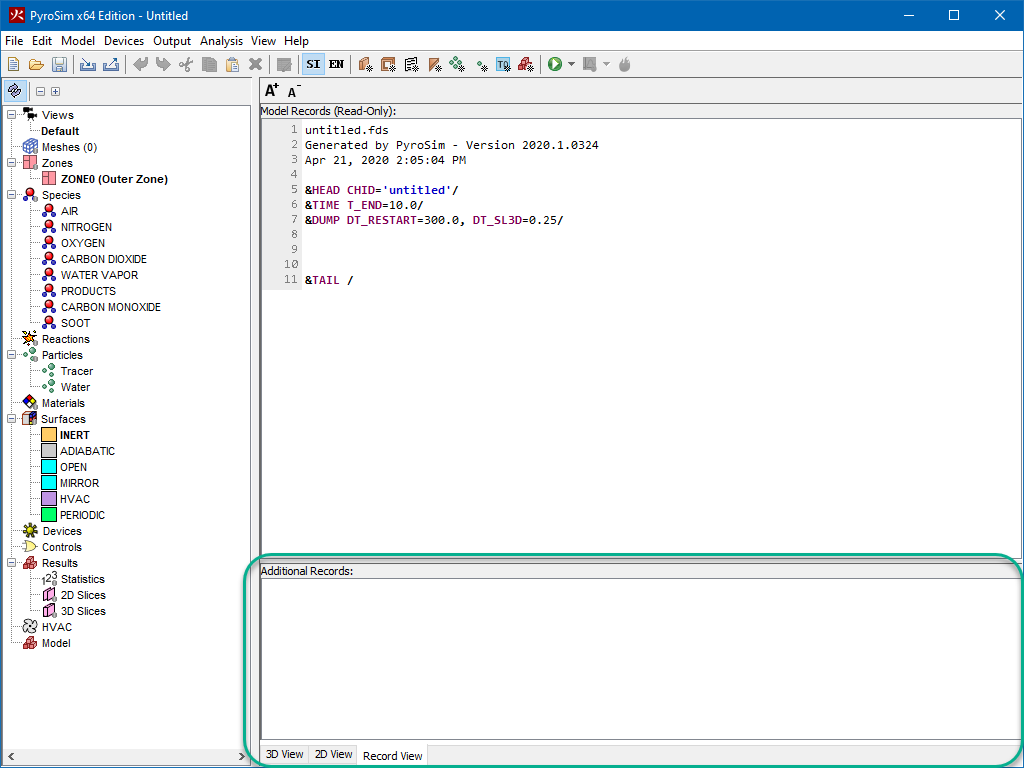

The Record View is shows an up-to-date display of the FDS input file currently represented by the PyroSim model. This view is divided into two sections, the Model Records and the Additional Records.

This read only sections allows the user to see an exact copy of the file that will be input into the FDS simulator based on their current model.

The user adjust font size of this using the Increase Font Size (![]() ) and Decrease Font Size (

) and Decrease Font Size (![]() ) buttons at the top of the page.

Other settings related to the file display can be toggled through the Preferences menu item.

) buttons at the top of the page.

Other settings related to the file display can be toggled through the Preferences menu item.

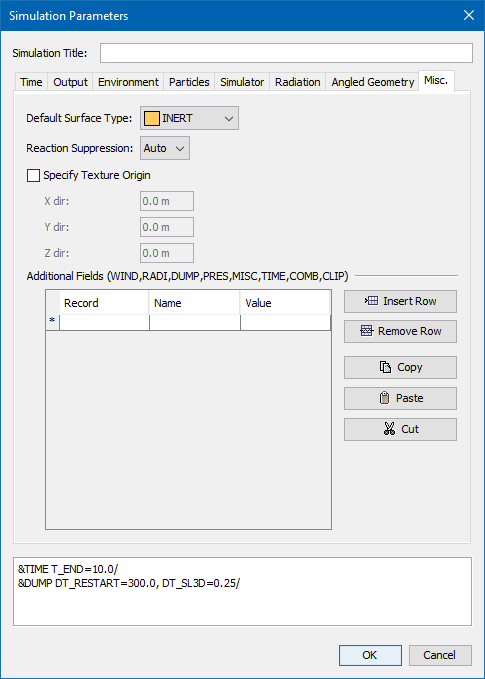

Due to the complexity of the FDS simulator, it is difficult to support all possible records and input files. The Additional Records section of the Record View can be used to inject lines of text into the top of the FDS input file.

Scenarios can be used to manage variations of a single model. Any time a simulation object is enabled or disabled, that change is retained by only the current scenario.

Multiple fire scenarios can be managed using the Scenarios box on the main toolbar. The Edit Scenarios dialog, activated by the toolbar button next to the Scenarios box, can be used to manage scenarios and examine which objects are enabled in a specific scenario.

For models that use multiple scenarios, a bulk export option is available on the File menu in the Export submenu, called Export Scenarios. Using this feature will export an FDS input file (and other supporting files) for each scenario in subfolders where the PSM file has been saved. A BAT file will also be produced that can be double-clicked in Windows Explorer to run all scenarios in sequence.

Images of the current display can be saved to a file by opening the File menu and clicking Snapshot. The user can specify the file name, image type (png, jpg, tif, bmp), and the resolution. A good choice for image type is Portable Network Graphics (png).

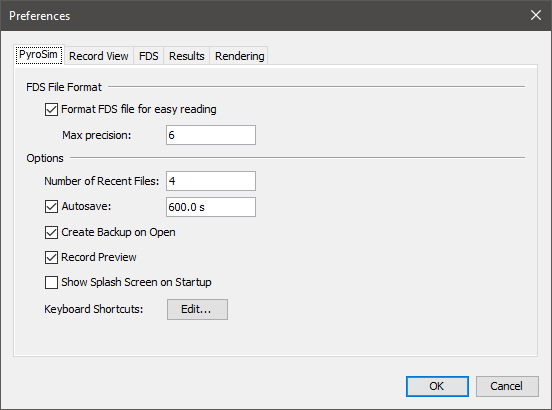

PyroSim preferences can be set by going to the File menu and choosing Preferences. Any changes to the preferences will be set for the current PyroSim session and be remembered the next time PyroSim is started. The preferences are split into several groups, including PyroSim, Record View, FDS, Results, and Display preferences.

These describe global PyroSim preferences as shown in Figure 13.

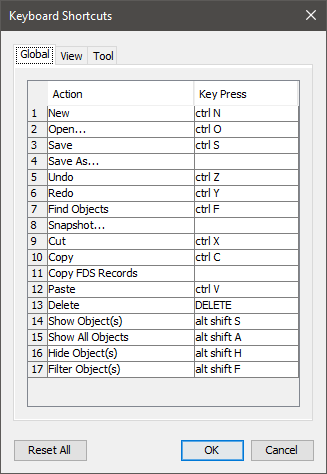

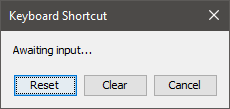

The Keyboard Shortcuts dialog is launched from the PyroSim preferences panel. These preferences bind combinations of modifier keys (ALT, CTRL, SHIFT, etc.) with other key presses to activate PyroSim actions.

The dialog is divided into three sections.

To change the keybinding for an action, click the value in the Key Press column. This launches an editor window (Figure 15) with four options.

Some keyboard shortcuts are used by Java UI components. If a shortcut does not result in the expected behavior, it may be in direct conflict with a preexisting Java shortcut. It is best practice to avoid these conflicts (Default Swing key bindings).

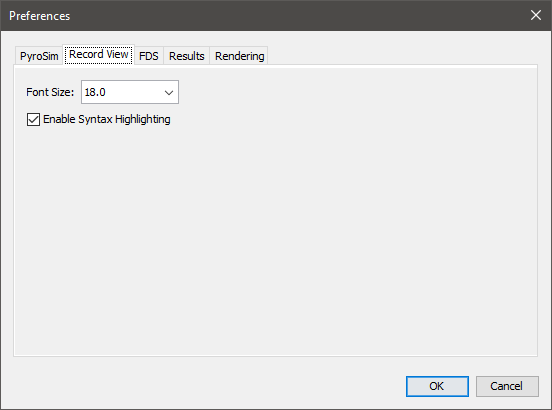

These preferences control the visualization of the FDS input file in the Record View. They can be seen in Figure 16.

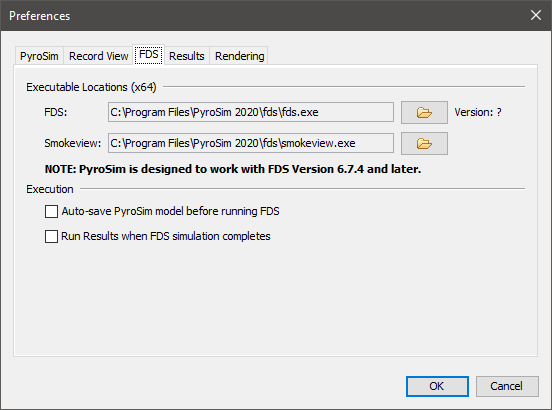

These preferences define the execution of FDS within PyroSim. They can be seen in Figure 17.

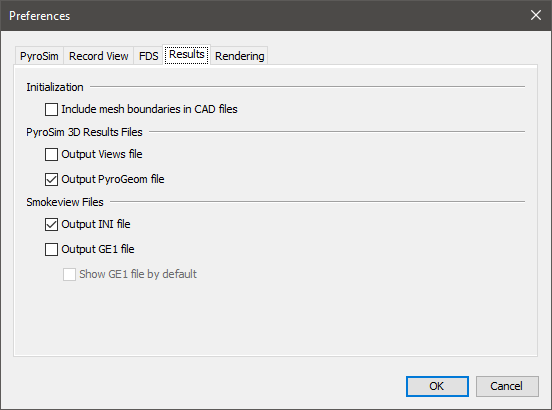

There are a number of preferences that control the files created by PyroSim when an FDS simulation is started that affect the results (either PyroSim 3D Results or Smokeview).

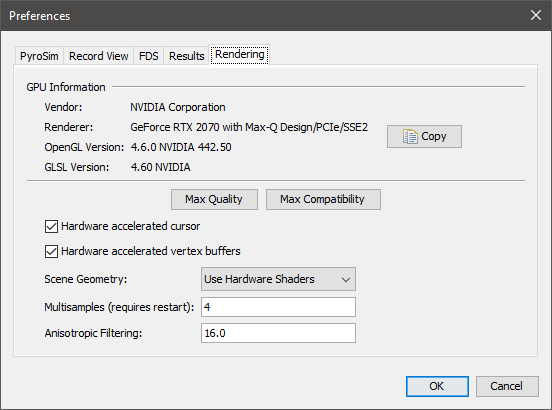

These preferences define advanced 2D and 3D display properties, as shown in Figure 19. They can be used to improve display performance on complex models, but they tend to create problems for some older graphics cards, including crashing. For this reason, they are turned off when running in safe mode.

PyroSim stores data related to user preferences in a file called PyroSim.props. By default, this file can be found in one of the following locations.

%APPDATA%\PyroSim\PyroSim.props%PROGRAMDATA%\PyroSim\PyroSim.props

If at least one of these files exists, PyroSim will use it to load the user preferences.

If both files exist, PyroSim will load user preferences from both files, giving preference to the file located in the APPDATA folder.

This way the preference file located in the PROGRAMDATA folder can be shared among multiple machines, and the file located in the APPDATA folder on each machine overrides the shared settings.

The PROPS file is stored in a plaintext format, and can be viewed or edited with any conventional text editor.

While it is not recommended to edit the file directly, some troubleshooting techniques may involve deleting the PROPS file so that a new one can be created from scratch by PyroSim.

Configurations for hotkeys in PyroSim is stored in a separate file named keybindings.json located in the APPDATA folder.

Models can be created in either English or Metric units. To select a system of units, on the View menu, click Units, then click the desired unit. PyroSim will automatically convert your previous input values into the unit system you select. The Record View will always display values in the appropriate FDS units, regardless of what unit system you choose to work in.

To select a Default, Black Background, White Background, or Custom color scheme, on the View menu, click Color Scheme.

The custom color scheme is defined in the PyroSim.props file in the PyroSim installation directory (For Windows 10 look in %USERPROFILE%\AppData\Roaming\PyroSim\PyroSim.props while some older operating systems use C:\Program Files\PyroSim).

PyroSim.props fileColors.Custom.axis=0xffff00 Colors.Custom.axis.box=0x404040 Colors.Custom.axis.text=0xffffff Colors.Custom.background=0x0 Colors.Custom.boundary.line=0xffffff Colors.Custom.grid=0x4d4d66 Colors.Custom.group.highlight=0xffff00 Colors.Custom.heatDetector=0xff0000 Colors.Custom.obst=0xff0000 Colors.Custom.obst.highlight=0xb2b200 Colors.Custom.origin2D=0x737373 Colors.Custom.smokeDetector=0xff00 Colors.Custom.snap.point=0xff00 Colors.Custom.snapto.grid=0x404040 Colors.Custom.snapto.points=0xc0c0c0 Colors.Custom.sprk=0xff Colors.Custom.text=0xffffff Colors.Custom.thcp=0xffff00 Colors.Custom.tool=0xff00 Colors.Custom.tool.guides=0x7c00

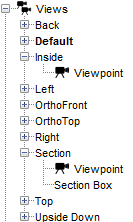

PyroSim.props filePyroSim provides the capability to save and recall view state from the 3D and 2D views in an object called a View. Views can also be used to specify clipping regions that limit the amount of the model shown in the 3D and 2D views. Views appear in the Navigation View as shown in Figure 20.

There can be multiple views in a model, but at any given time, there is always one active view. A new model will always start with one default view that has no view state associated with it. State can be added to the view as described in the sections, Viewpoints and Section Boxes.

Views are managed in the navigation view. From there, they can be created, deleted, grouped, rearranged, etc.

A view can be created in one of the following ways:

This will add a new view to the model, saving the current camera viewpoint and section box into the new view (see the following sections to learn more about viewpoints and section boxes). The new view will become the active view.

To delete a view, select it in the navigation view and in the Edit menu, select Delete. A view can only be deleted if it is not active.

To activate a view, perform one of the following:

Activating a view will restore all its saved state as described in the following sections.

View settings can be copied or moved between views. To copy settings such as the viewpoint or section box select Copy, located in either the navigation view or in the Edit menu. To paste the settings to another view, select the desired target view and in the Edit menu select Paste. To move settings from one view to another, in the navigation view, drag the setting to the desired view.

Each view can have one viewpoint associated with it. A viewpoint includes the 2D or 3D camera’s position, orientation, zoom, and camera type (3D versus 2D). When a viewpoint is saved, the current navigation tool is also saved with the view (Orbit, Roam, etc.). A viewpoint appears in the navigation view as a child item of a view and is labelled Viewpoint. This can be seen in Figure 20 for the two views, Inside and Section.

A viewpoint is automatically saved to newly created views. A viewpoint can also be explicitly saved in one of the following ways:

The scene camera can be reset to a viewpoint in one of the following ways:

A viewpoint can be removed from a view by selecting the item, Viewpoint, in the navigation view and deleting it.

When a view with a viewpoint is activated, the following occurs:

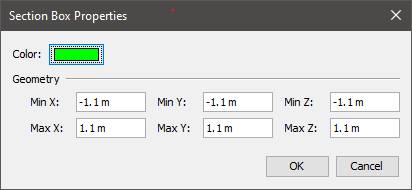

A section box may also be added to a view. A section box is a convex region defined by six sides that is used to limit the scope of visible geometry. All geometry outside the box is clipped from view. An example of the clipping is shown below.

A section box can be created in several ways:

A section box is displayed as a dashed outline of the region. Each section box has a color associated with it that is used to display both the outline of the section box and the clipped portions of solid, clipped objects as shown in Effect of a Section Box, Figure 21. In this figure, the section box is green, so any geometry that is clipped including the walls and slab in the image are also colored green.

The scope of a section box can be edited by selecting the section box and manipulating it like any other geometric object, see Editing Objects. Section boxes can also be rotated and moved like other geometric items, see Transforming Objects.

The properties of a section box can be edited by either double-clicking the section box or by right-clicking it and selecting Properties.

See Figure 23 below.

The active section box can be disabled in the 2D or 3D view by de-selecting Enable Section Boxes in the View menu. The display for the section box can be independently hidden from view by de-selecting Show Section Boxes in the View menu.

A section box can also be reset to encompass the currently visible objects by performing one of the following:

Smokeview supports the concept of viewpoints, which are similar to PyroSim views. Smokeview viewpoints are defined by camera position, orientation, a navigation tool, and up to six axis-aligned clipping planes. Viewpoints are stored in the Smokeview INI file.

By default, when PyroSim prepares an FDS simulation or exports an FDS file, it also writes a Views file that can be read in the PyroSim 3D Results but not Smokeview. It does not write the views to the Smokeview INI file. This is to avoid view duplication in the 3D Results. This behavior can be changed, however, by turning off the Views file in the preferences, see Preferences. If turned off, PyroSim will instead write the view information to the INI file, which can be read in Smokeview.

At any time, the view information can be updated for the results without re-running the simulation by explicitly writing either the PyroSim Views file or the Smokeview INI file. This can be done by going to the File menu, and selecting either Export→PyroSim Viewpoints or Export→Smokeview INI, respectively.

While the Views file exports views exactly as defined in PyroSim, there are some limitations to how PyroSim views are exported to the Smokeview INI file:

In addition, if a view was saved in PyroSim with the Roam tool active, the Rotation type in Smokeview is set to Eye centered. For all other navigation tools, the Rotation type in Smokeview is set to 2 axis.

Smokeview viewpoints may also be imported into PyroSim. This is useful if additional views have been specified in Smokeview while viewing the results and those viewpoints should be preserved in PyroSim. To import Smokeview viewpoints, perform the following:

After importing, a new view group is added, containing one PyroSim view for each Smokeview viewpoint that was in the INI file.

Several files are used when performing a fire analysis using PyroSim. These include the PyroSim model file, the FDS input file, and FDS output files. This section describes how to load and save files in the formats supported by PyroSim.

When PyroSim is started, it begins with an empty model. You can close the current model and create a new empty model by opening the File menu and clicking New. PyroSim always has one (and only one) active model.

The PyroSim model file (PSM) is stored in a binary format that represents a PyroSim model. The PyroSim model contains all the information needed to write an FDS input file, as well as additional information such as obstruction grouping, floor heights, background images, and textures. This format is ideal for sharing your models with other PyroSim users.

To save a new model:

PyroSim model files have a PSM extension. To open a saved model:

A list of recently opened files is also available. To open recent files, on the File menu, click Recent PyroSim Files, then click the desired file.

PyroSim has an auto-save feature which stores a copy of your current model every 10 minutes. This file is automatically deleted if PyroSim exits normally, but if PyroSim crashes, you can recover your work by opening the autosave file. It can be found either in the same directory as your most recent PSM file, or in the PyroSim installation directory if your model was unsaved.

For more information about opening files saved with previous versions of PyroSim, please refer to Appendix A and Appendix B.

PyroSim supports write protection for a model. When write protection is enabled, users cannot modify a model (e.g. change geometry, edit surface properties, etc). This option can be enabled with or without password protection. If a model is write-protected, PyroSim will display notification in the application title bar.

To add write protection to a model:

The model will now be write-protected. Since a password was not used, a password will not be required to remove write protection.

To remove write protection from a model:

The model can now be edited. If needed, the dialog will require a password to release the lock.

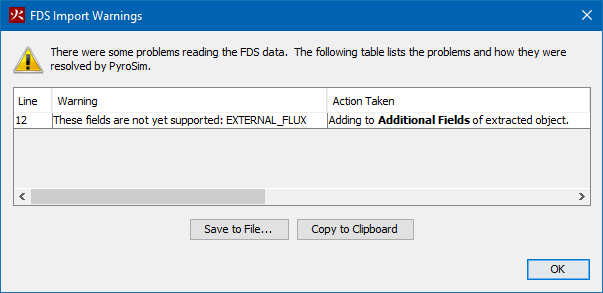

PyroSim allows you to import existing FDS input files. When you import an FDS file, PyroSim will create a new PyroSim model from the imported file. During import, PyroSim will check for the validity of each record. If errors are detected, you will be notified. You may then make the required corrections and attempt to import the file again.

To import existing FDS models into PyroSim:

PyroSim supports file import for versions 4, 5, and 6 of FDS. For more information about opening files compatible with version 4 or 5 of FDS, please refer to Appendix A and Appendix B.

PyroSim also allows you to explicitly export the current model to an FDS input file. You can manually edit the file to take advantage of advanced FDS features, or to easily transfer the input file to a different machine or special version of FDS.

To export an FDS file:

The file exported by PyroSim will be compatible with version 6 of FDS.

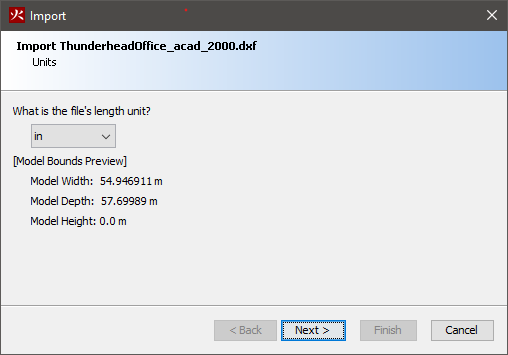

PyroSim can import geometry from several CAD formats, including buildingSMART’s IFC format for Building Information Models (BIM), AutoCAD’s DXF (Drawing Exchange Format), DWG, FBX, DAE, OBJ, and STL files. Each type of file provides a variety of geometry that can either be directly represented as obstructions or as drawing guides in the PyroSim model.

Unlike FDS import, which completely replaces the current PyroSim model, CAD import appends the data to the current model. This facilitates the ability to import data from several CAD files into one PyroSim model. This is useful when there is one blueprint per floor of a building or a 3D building has been split into several sections, each in a separate file.

To import one of these files, under the File menu, select Import FDS/CAD File and select the desired file.

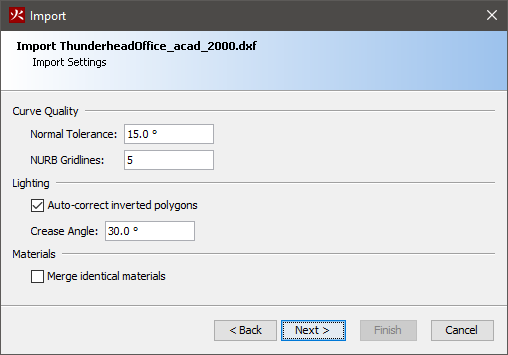

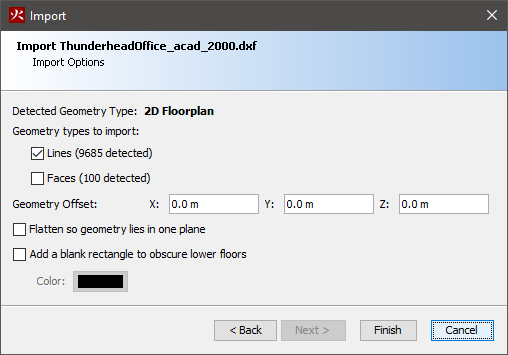

STL files will import as shown in Importing STL Files. For non-STL files, a step-by-step dialog will open as shown in Figure 24.

Choose Finish to import the file.

When PyroSim imports a CAD file, it will treat all 3D face data as obstructions and all other data (lines, curves, etc.) as separate CAD data. If an object in the file contains both face and CAD data, the entity will be split into two entities so that CAD data can be easily deleted or hidden after import using the CAD filter button on the 3D/2D View toolbar, see Filtering.

An object with CAD data can be snapped to while drawing in PyroSim but is not converted to any type of FDS geometry.

In DWG and DXF files, an entity with face data will either be treated as a single, solid obstruction with some volume or as a collection of thin obstructions depending on the entity type in the DWG/DXF file. These objects will be represented as FDS geometry. The following DWG/DXF entity types are treated as solids in PyroSim:

With the exception of IFC files, all other entities and objects from other CAD formats that contain faces are treated as collections of thin obstructions by PyroSim. They cannot be reliably treated as solid since there is no guarantee that their faces form a closed and non-self-intersecting shell or that this would even be desired.

Once the file is imported, PyroSim creates a hierarchy of groups and objects, such that there is one top group, named after the file. The next levels depend on the imported file type. For non-DWG/DXF files, the structure will mimic the node structure in the source file. For DWG/FXF files, the next level contains a group for every layer containing geometry. Under each layer group there are one or more objects representing the entities in the file. The following illustrates the hierarchy as it would appear in the Navigation View:

If the DWG/DXF file contains a block insert and the block contains entities from multiple layers, the block insert is split into several PyroSim objects, one for each layer of the block’s originating entities. If all the entities in the block are from the same layer, however, there will be one resulting PyroSim object that will belong to the group corresponding to the block’s entities' layer rather than the block insert’s layer.

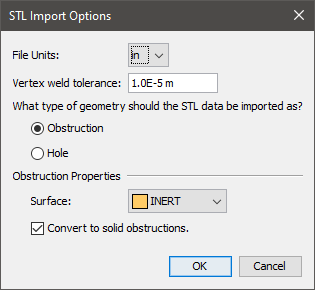

PyroSim can also import objects from STL files, which are simply listings of triangles. Usually, each STL file represents the shell of one 3D solid object.

To import an STL file, perform the following:

In Figure 27, the following options can be specified:

Because the STL file is simply a listing of triangles, there may be more than one object represented in the file. PyroSim will use the vertex weld tolerance to detect triangle connectivity and determine if there are several, disconnected sets of faces in the file. If there are, there will be one resulting PyroSim object per connected set of faces.

In addition, if the solid option is enabled or the objects are being treated as holes, import will only succeed if each face set is detected as a closed shell by PyroSim.

While PyroSim cannot directly import Autodesk Revit files (RVT), there are several ways to export the data from Revit into a file format that PyroSim can read. Each method has advantages and disadvantages as discussed below.

C:\ProgramData\Autodesk\Revit\Addins\SimLab\FBXExporter\data\Imported_Textures\#Some CAD files contain 2D floor plans, which, on their own, cannot be used in a simulation. These types of files must first be converted into solid 3D geometry. There are two ways in which this can be accomplished.

The first involves using the floor plan as a guide to draw the 3D model. See Drawing in PyroSim for more information.

The second is to convert lines that represent walls into 3D walls using automated tools. This can be done as follows:

This will replace each line with a 3D wall, whose base is centered on the original line.

All FDS calculations are performed within computational meshes. Every object in the simulation (e.g. obstructions and vents) must conform to the mesh. When an object’s location doesn’t exactly conform to a mesh, the object is automatically repositioned during the simulation. Any object that extends beyond the boundary of the physical domain is cut off at the boundary. There is no penalty for defining objects outside of the domain, but these objects do not appear in the Results.

To achieve optimal simulation accuracy, it is important to use mesh cells that are approximately the same size in all three directions.

FDS uses a Poisson solver based on Fast Fourier Transforms (FFTs). A side effect of this approach is that optimal mesh divisions are constrained to the form 2u 3v 5w, where u, v and w are integers. For example, 64 = 26, 72 = 23 * 32, and 108 = 22 * 33 are good mesh dimensions. However, 37, 99 and 109 are not. In addition, using a prime number of cells along an axis may cause undesirable results. PyroSim warns when the number of divisions is not optimal.

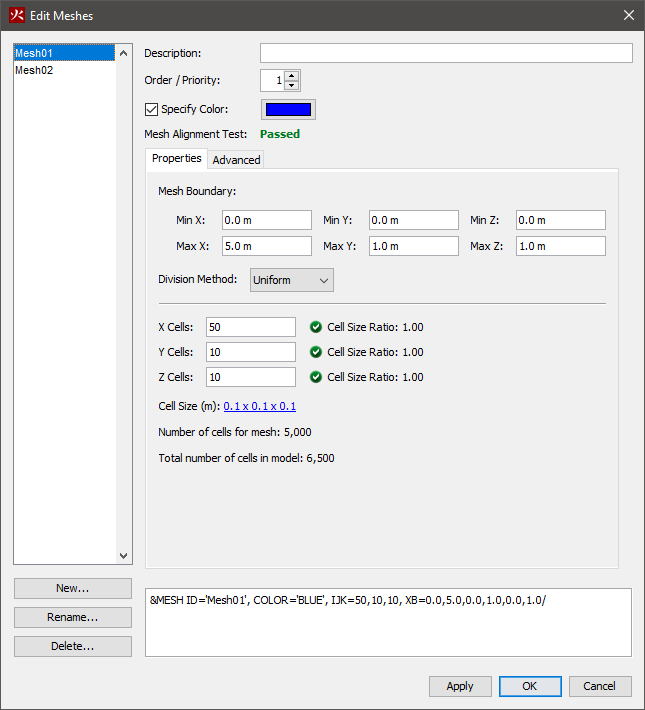

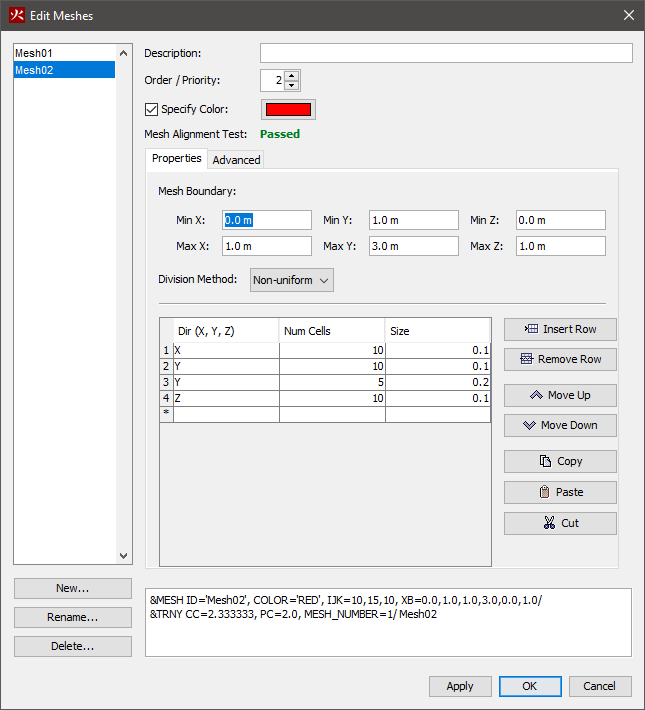

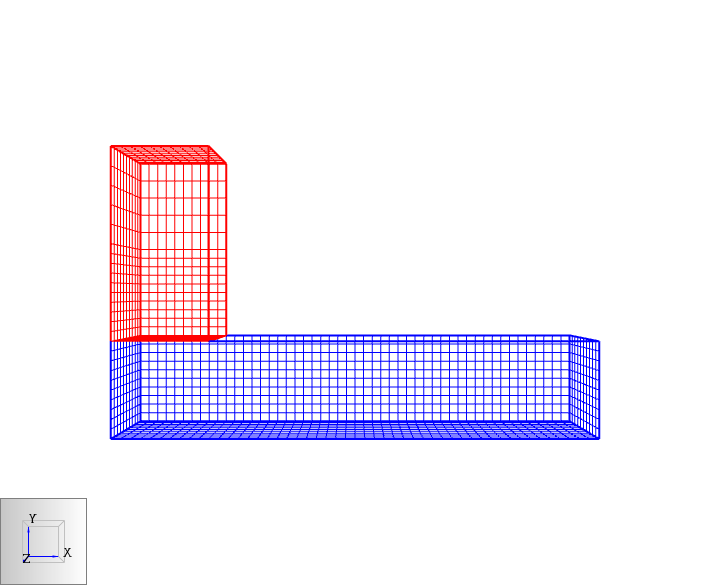

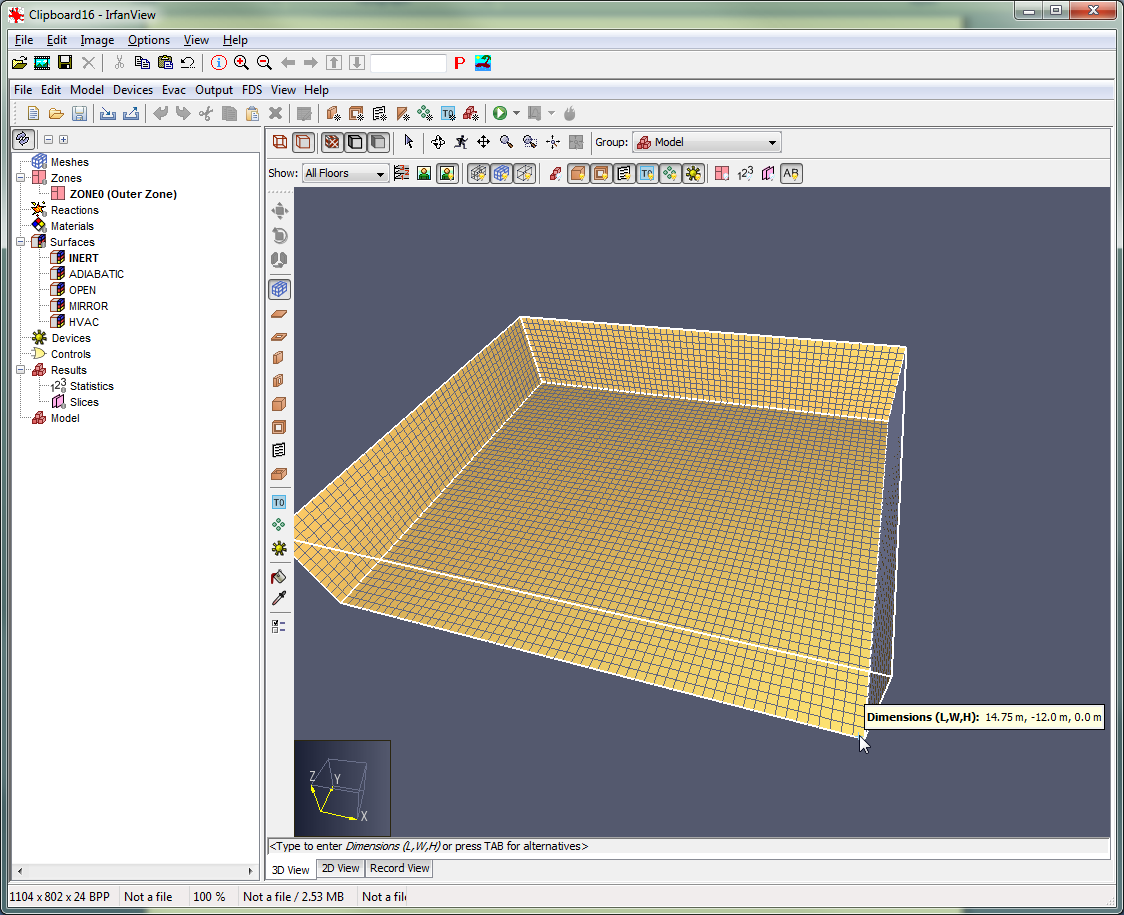

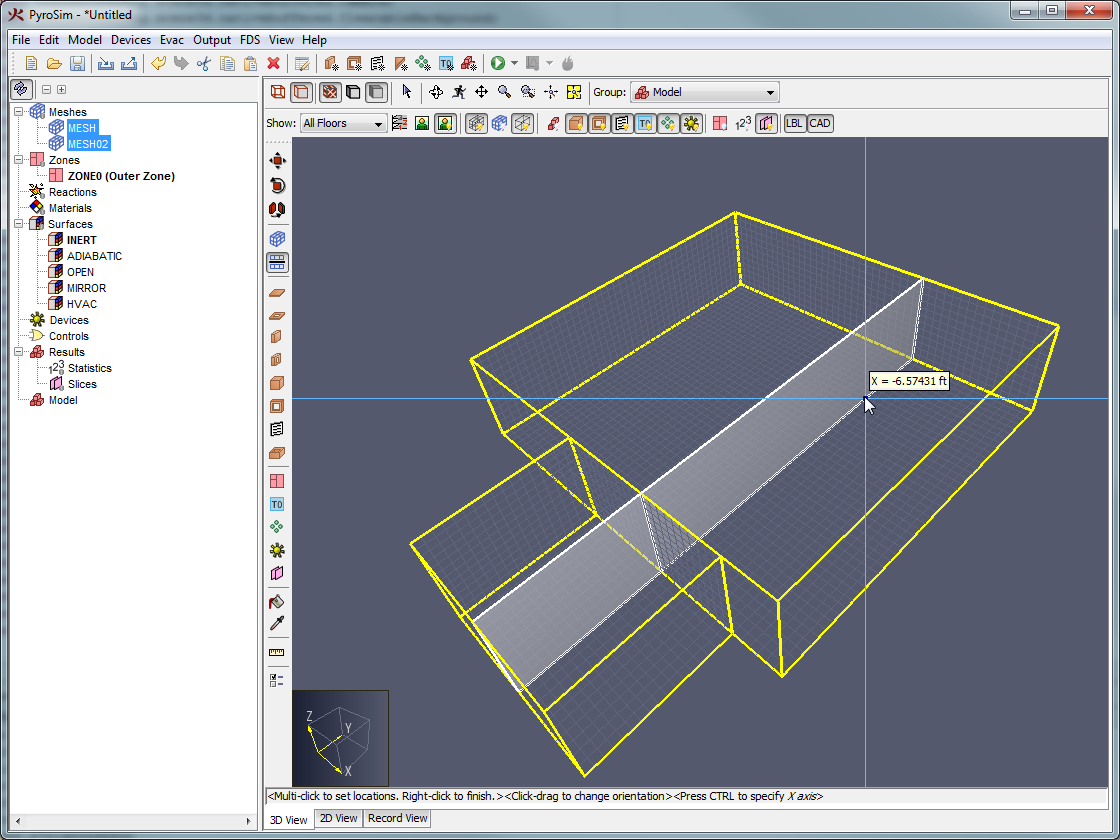

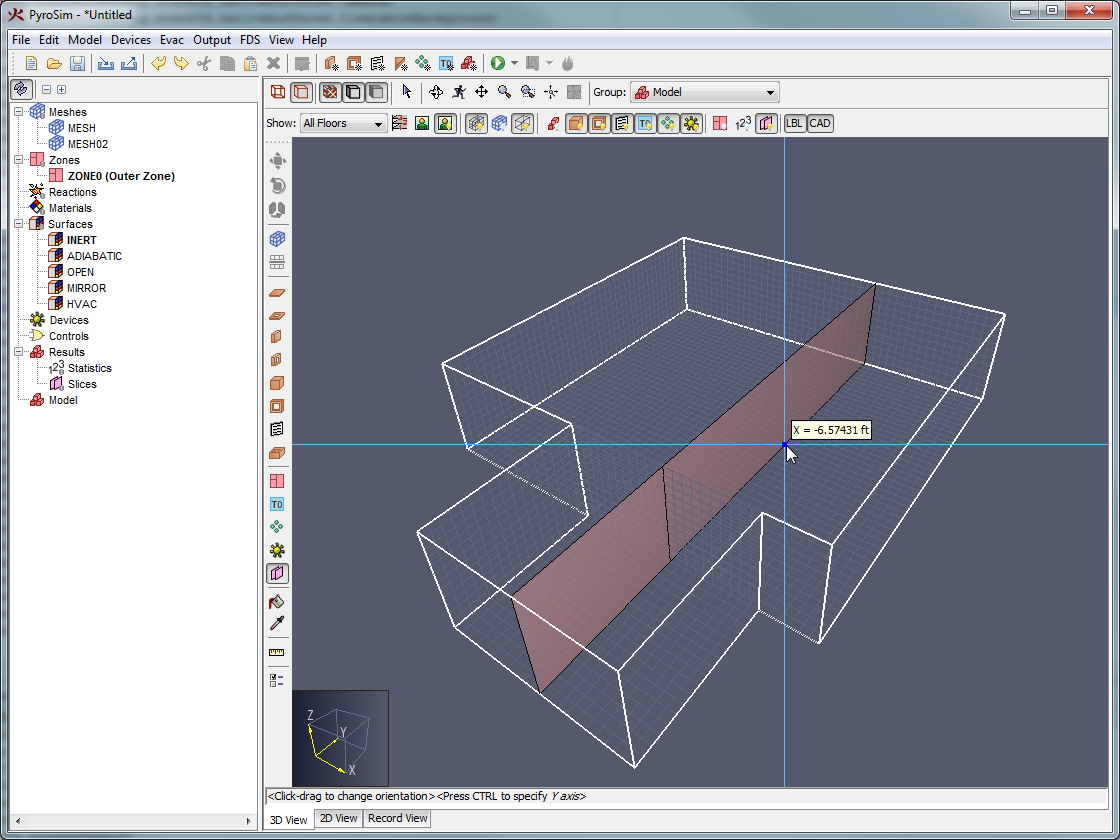

This example illustrates creating a multiple mesh model.

To create the first mesh:

The 3D View will now display the resulting mesh.

To create a second, nonuniform mesh:

In the table, enter the data shown in Table 2

| Dir (X,Y,Z) | Num Cells | Size |

|---|---|---|

| X | 10 | 0.1 |

| Y | 10 | 0.1 |

| Y | 5 | 0.2 |

| Z | 10 | 0.1 |

You can click ![]() or type Ctrl+R to reset the model.

The resulting meshes are displayed below.

or type Ctrl+R to reset the model.

The resulting meshes are displayed below.

The term "multiple meshes" means that the computational domain consists of more than one rectangular mesh, usually connected, although this is not required. In each mesh, the governing equations can be solved with a time step based on the flow speed within that particular mesh. Some reasons for using multiple meshes include:

Meshes can overlap, abut, or not touch at all. In the last case, essentially two separate calculations are performed with no communication at all between them. Obstructions and vents are entered in terms of the overall coordinate system and need not apply to any one particular mesh. Each mesh checks the coordinates of all the geometric entities and decides whether or not they are to be included.

As described in the FDS User Guide (McGrattan et al. 2021) the following rules of thumb should also be followed when setting up a multiple mesh calculation:

To simplify working with multiple meshes, PyroSim provides the following additional mesh operations:

To use any of the above actions, select one or more meshes, right-click to open a popup menu, then click the desired mesh action.

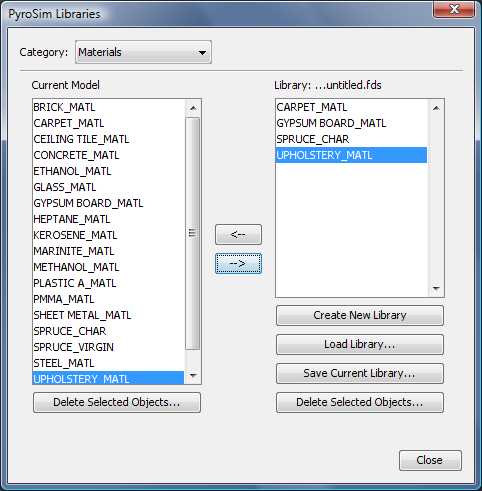

To simulate a surface made of heat-conducting solids or a fuel you must specify a material that describes certain thermal properties and pyrolysis behavior. PyroSim offers two categories of materials: solid materials and liquid fuels.

To create a new material, you can use the Edit Materials dialog. On the Model menu, click Edit Materials.

Examples of solid materials include brick, gypsum board, and upholstery. To create a solid material:

After following these steps, a default solid material will be created. Text entered in the Description box will not affect the simulation, but will be preserved in the FDS input file using the FYI field of the material. Including a description of the material is recommended.

The Thermal Properties tab provides the following options:

The Pyrolysis tab provides options to set the heat of combustion and add reactions that will be used to govern how the material burns.

Each material can have a maximum of 10 reactions. To add a reaction, click the Add button. This will open a dialog to edit the new reaction. It provides the following options:

On the Rate tab:

On the Byproducts tab:

Examples of liquid fuels include kerosene and ethanol.

To create a liquid fuel:

After following these steps, a default solid material will be created. Text entered in the Description box will not affect the simulation, but will be preserved in the FDS input file using the FYI field of the material. Including a description of the material is recommended.

The thermal properties tab for liquid fuels is identical to the thermal properties tab for solid fuels, see Solid Materials.

The Pyrolysis tab provides the following parameters:

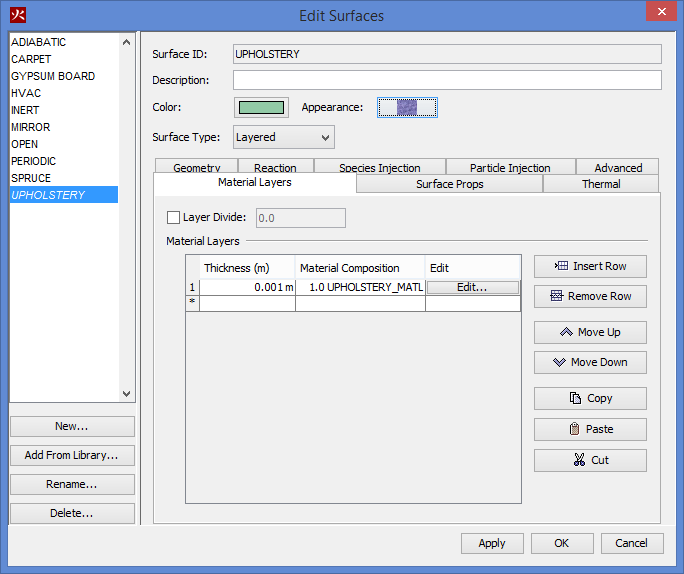

Surfaces are used to define the properties of solid objects and vents in your FDS model. The surface can use previously defined materials in mixtures or layers. By default, all solid objects and vents are inert, with a temperature that is fixed at the ambient temperature (set in the Simulation Parameters dialog). In addition to defining heat conduction in a solid, surfaces can also be used to define a burner, specify the ignition temperature for an object, give a vent a supply velocity, and set the many other properties supported by FDS.

To create, modify, and delete surfaces, you can use the Edit Surfaces dialog. To open the Edit Surfaces dialog, on the Model menu, click Edit Surface Properties. The dialog in Figure 35 shows the dialog being used to edit an upholstery surface.

There are six fundamental or "reserved" surface types: ADIABATIC, INERT, MIRROR, OPEN, HVAC, and PERIODIC. These surfaces cannot be changed and are present in every analysis.

This surface remains fixed at the ambient temperature. Heat transfer does occur from gases to INERT surfaces.

This surface is used only for vents on the exterior mesh boundary. A MIRROR is a no-flux, free-slip boundary that reverses flow. It is intended to be applied to an entire mesh boundary to symmetrically double the size of the domain.

PyroSim aids the user by organizing the surface options into logical types, such as a burner to define a simple fire or a layered surface to represent a solid, heat conducting wall.

There are eight surface types in alphabetical order that you can create in PyroSim.

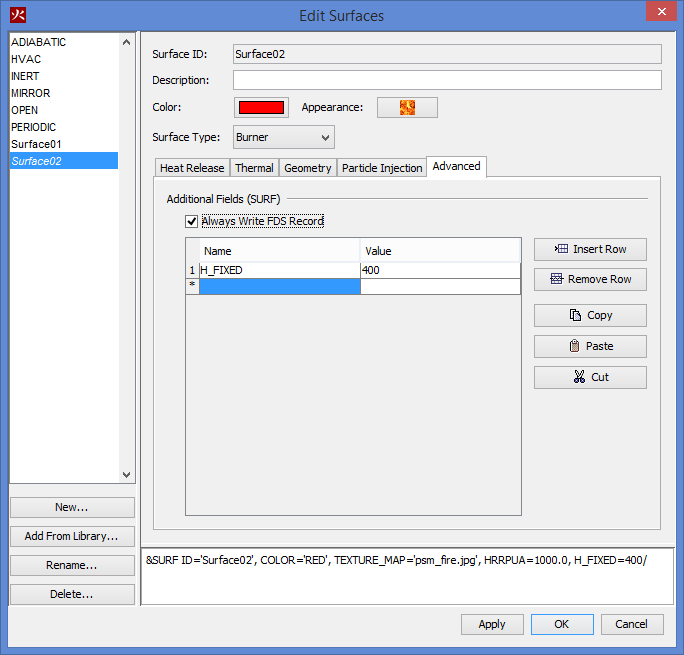

The Edit Surfaces dialog helps define a surface type with a set of tabs. Each tab provides a collection of input fields and settings for the user to customize that surface type.

Air leak surfaces can be used to create a permeable barrier between two pressure zones, defined by the Leak Path in the Edit Surfaces dialog. The leak area is defined by the zones selected.

This surface type is identical to the built-in INERT surface type. It allows you to customize the description, color, and texture of the inert surface described in Reserved Surfaces.

Tabs: Advanced, Properties (only on this Surface Type)

This surface type represents a fire with a known heat release rate or mass (fuel) loss rate.

Tabs: Advanced, Geometry, Heat Release, Particle Injection, Thermal

Exhaust surfaces can be used to remove gas from the simulation domain. The specification of their air movement parameters is identical to that of a supply surface, but instead of the velocity or flux driving air into the domain, they are pulling air out. Exhaust surfaces do not have the option to apply injection or geometry properties.

The General Surface type is a hybrid between the Burner and Supply surface types. Adding a little more flexibility than either of them individually.

Tabs: Advanced, Air Flow, Geometry, Heat Release, Particle Injection, Species Injection, Thermal

This surface type represents a radiative heat source. The options are identical to the options for a burner without the heat release options. If the surface temperature is less than the ambient temperature, the surface will remove heat from the surrounding gases.

Tabs: Advanced, Geometry, Particle Injection, Thermal

Layered surfaces are composed of one or more material definitions. Materials include solid and liquid substances such as concrete, pine, and ethanol. For more information about materials and how they can be specified in PyroSim, please refer to Materials. This type of surface is ideal for walls and other objects that are composed of real-world materials. This surface type can also be used to inject extra (non-reactive) species into the simulation.

Tabs: Advanced, Geometry, Material Layers, Particle Injection, Reaction, Species Injection, Surface Props, Thermal

This surface represents a vent that injects air into the simulation domain. The temperature of the air injected by supply vents can be controlled using settings on the thermal tab. Species Injection options are available if the Specify Mass Flux of Individual Species option in the Air Flow group is selected and there are extra, non-reactive species present in the simulation.

Tabs: Advanced, Air Flow, Geometry, Particle Injection, Species Injection, Thermal

Each tab of the Edit Surfaces dialog provides a set of inputs and settings that can be used to build a custom surface type as listed in Surface Types. The following sections describe the parameters on each tab and are listed in alphabetical order, not the order they might appear for a surface type.

Sometimes there will not be UI elements in PyroSim for an FDS input parameter that you want to configure. The Advanced tab can be used to enter Additional Fields as Name and Value pairs that will be placed into that specific FDS &SURF record. For more information about custom FDS record input that is not supported by the PyroSim UI, see Advanced Parameters.

The reaction used to model a given surface can either be taken from the material specifications, or given explicitly by the surface. Manually specifying the parameters will produce a surface similar to a burner.

You can edit this behavior using the reaction options:

You can inject extra (non-reactive) species into the simulation using the species injection options. To use these options, you must first specify species using the Edit Species dialog.

You can edit the following species options:

You can add textures to surfaces to increase the realism of your model. This can be done through the use of Appearance objects.

An Appearance defines how the surfaces of objects will appear and can have colors or textures applied to them. Some default appearances are provided or you can import your own. The Room Fire example demonstrates using a wood texture for a pine floor and hanging a picture on a wall. Your textures will be automatically displayed in PyroSim. Appearances will be shown on obstructions and vents when the View Mode is either Realistic or Realistic with Outlines.

To define an appearance with a texture and attach it to a Surface:

Appearances can also be viewed by going to the Model menu and selecting Edit Appearances.

PyroSim provides tools to help the user rapidly create and organize model geometry.

Geometry can either be created through dialogs or by using the drafting tools in the 2D or 3D views as discussed in Drawing in PyroSim.

There are typically three types of geometry that can be created in PyroSim:

The user can also organize the model by creating floors and groups. In addition, the user can assign background images to floors to aid in drafting.

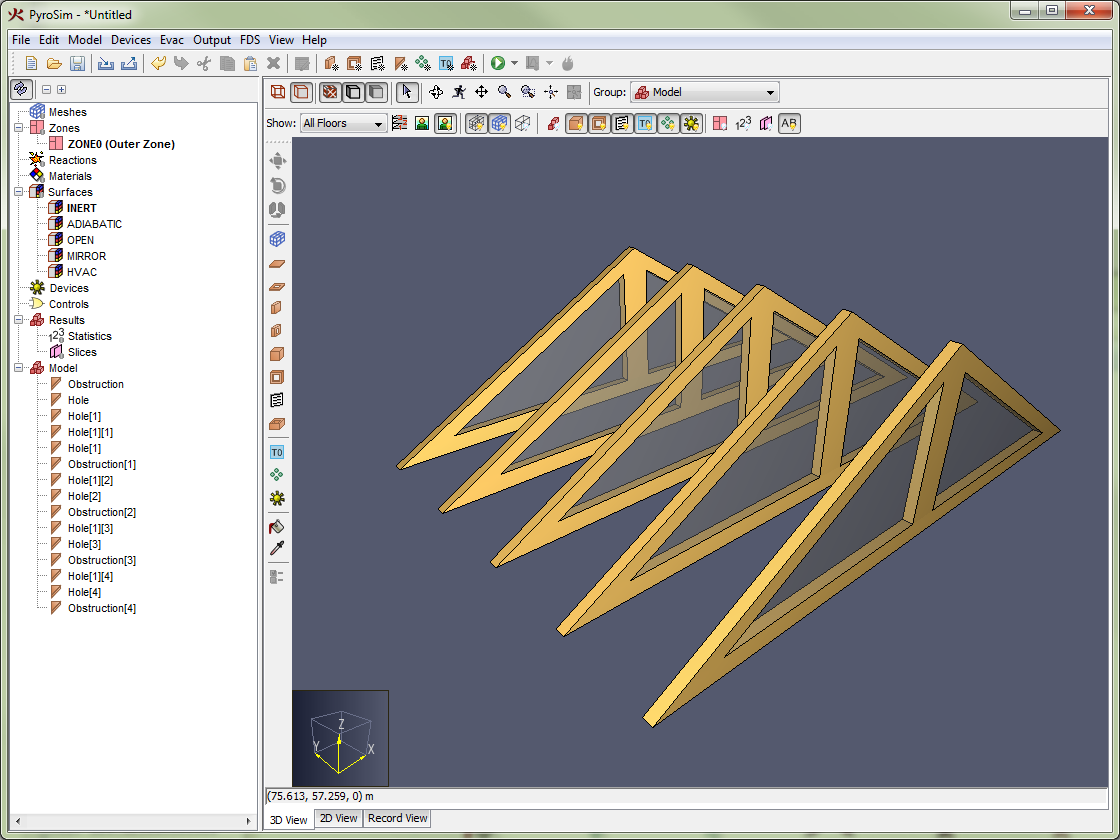

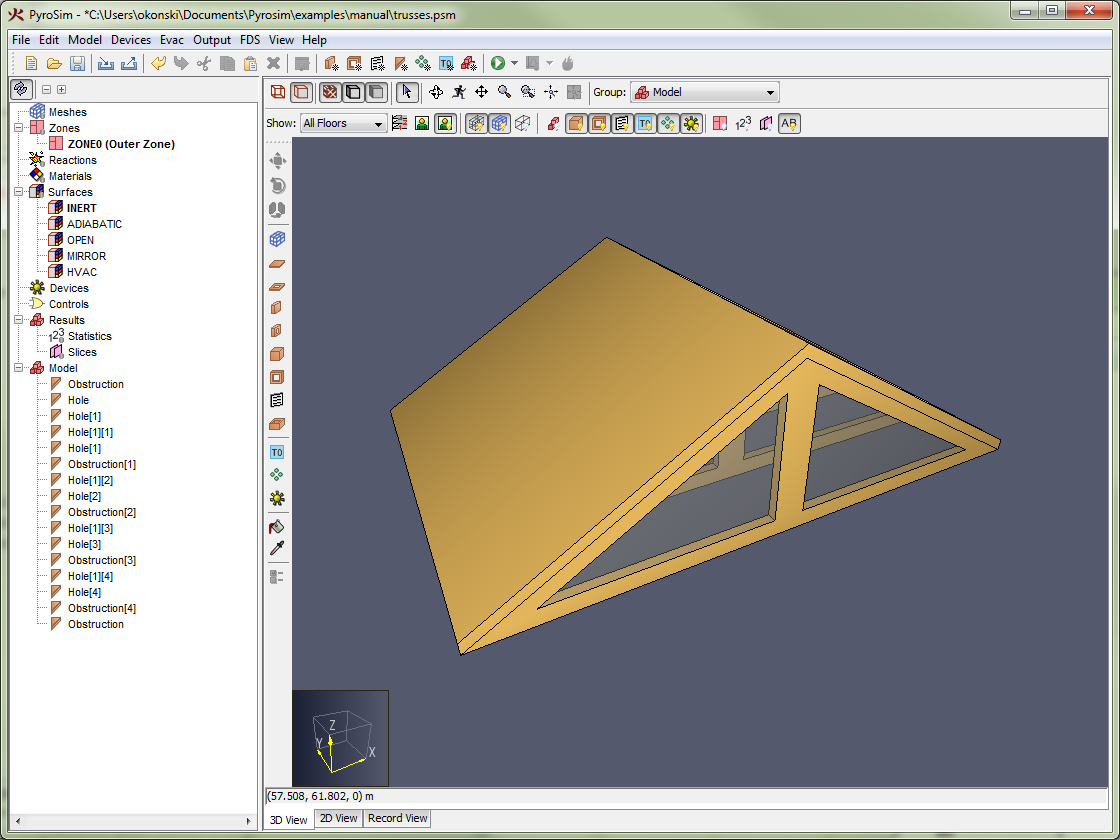

Obstructions are the fundamental geometric representation in FDS. In FDS, obstructions are rectangular, axis-aligned solids defined by two points. Surface properties are assigned to each face of the obstruction. In PyroSim, obstructions can take any shape, have any number of faces, and have different surfaces applied to each face. At the time of simulation, PyroSim will automatically convert the obstructions to axis-aligned blocks required by FDS as discussed in Angled Geometry.

FDS defines two types of obstructions:

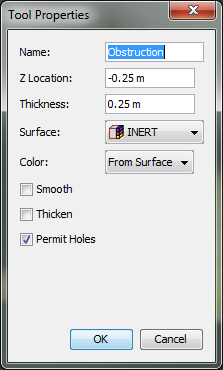

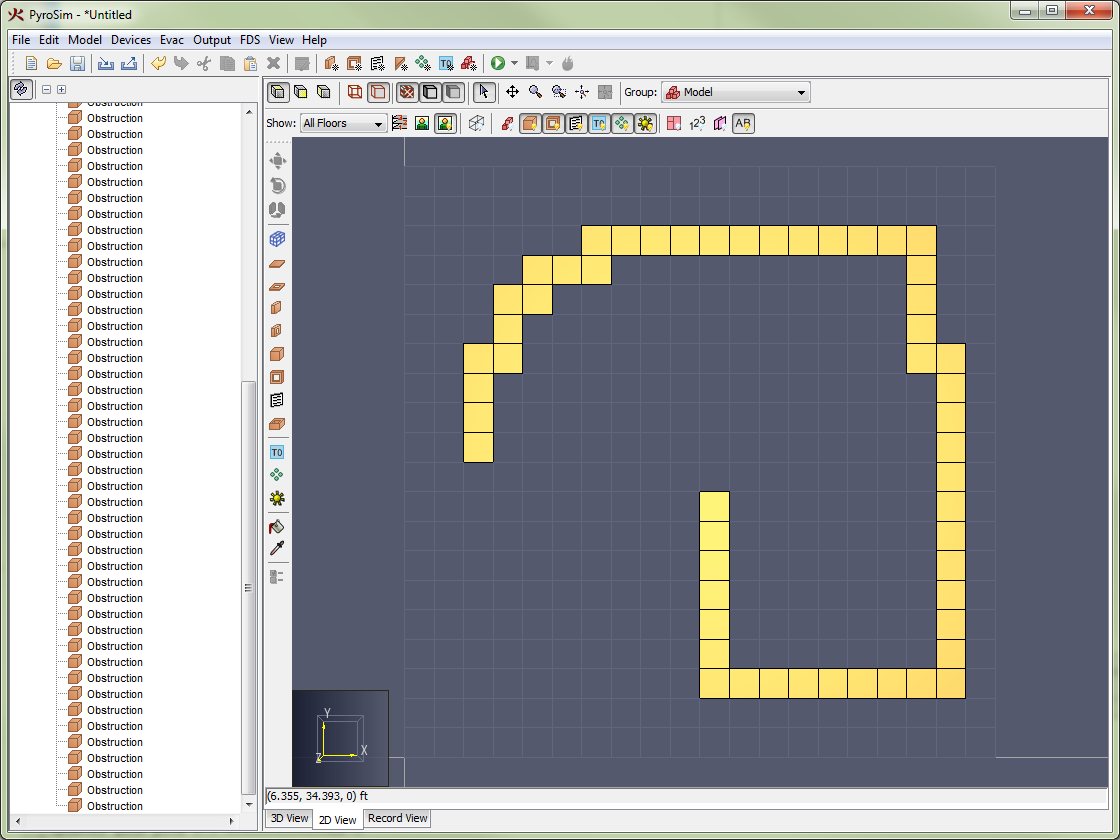

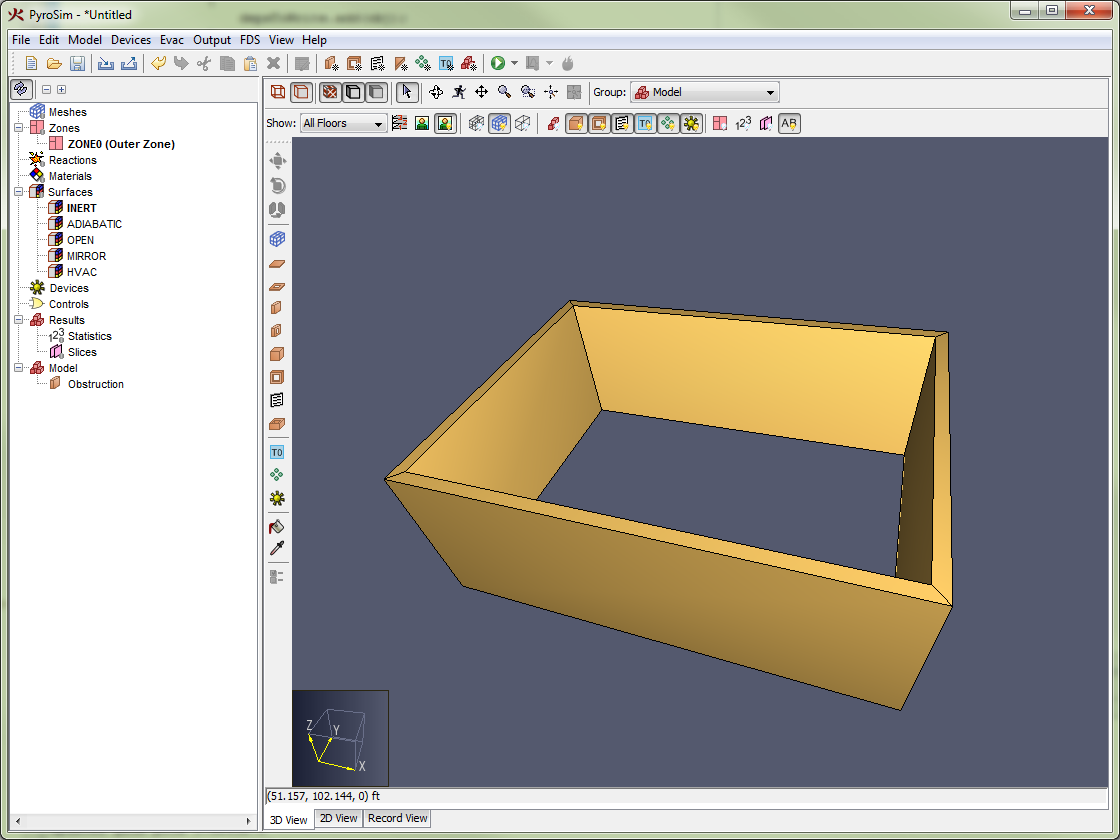

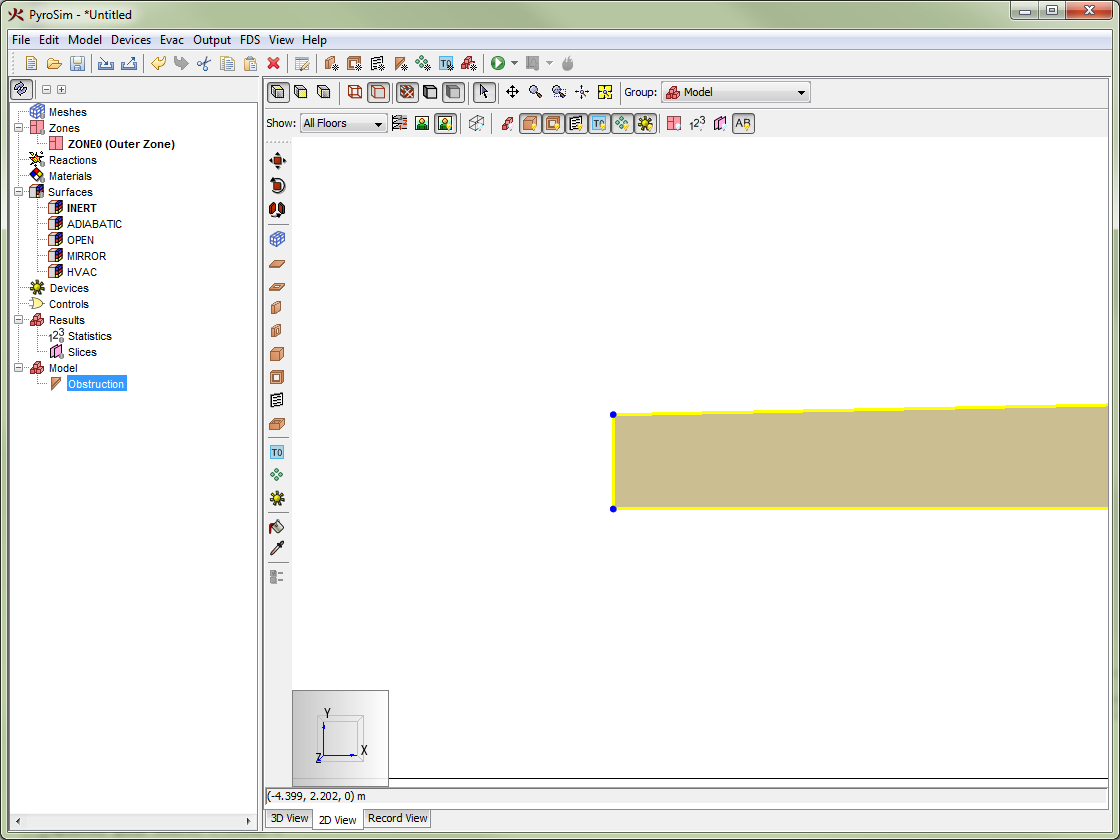

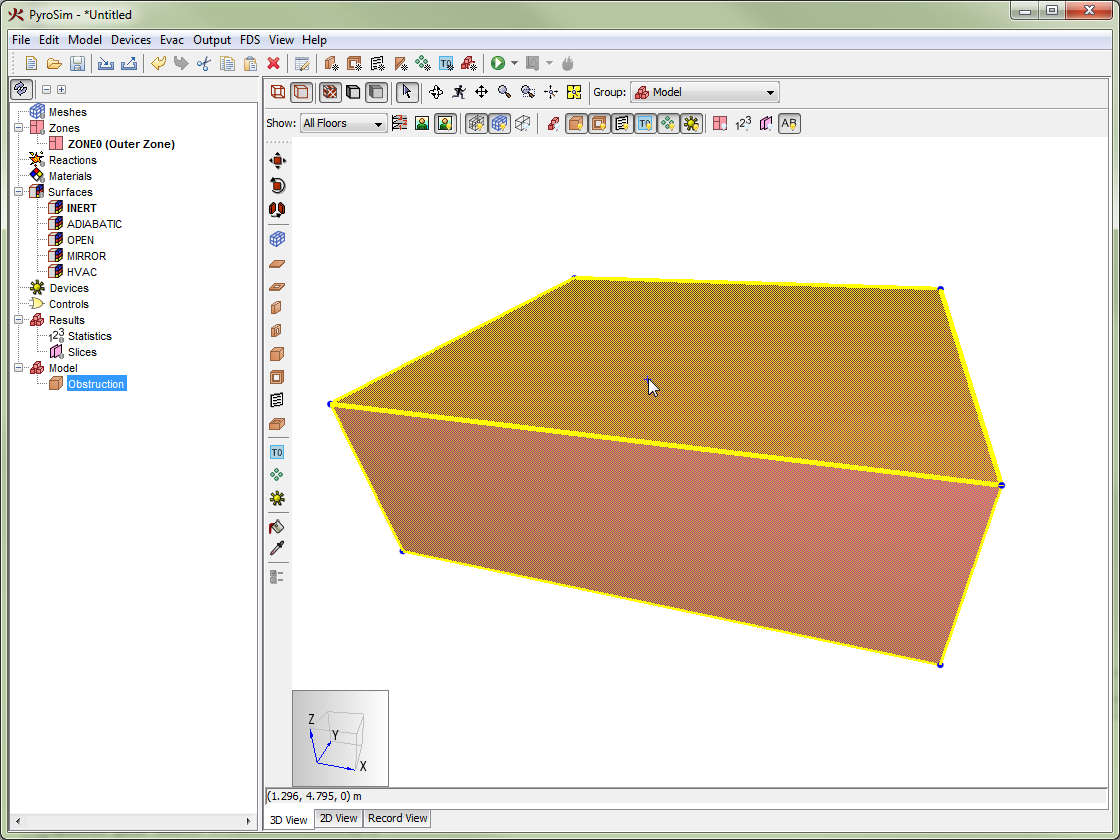

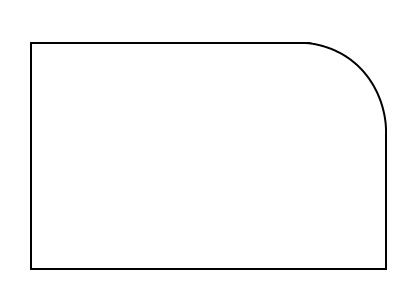

Conversion of a slab obstruction to FDS blocks shows an example of a polygonal slab drawn in PyroSim (Figure 37) and its conversion to blocks for use in FDS (Figure 38).

To create a new obstruction, either use an obstruction drawing tool as discussed in Drawing in PyroSim or on the Model menu, click New Obstruction. or New Slab.

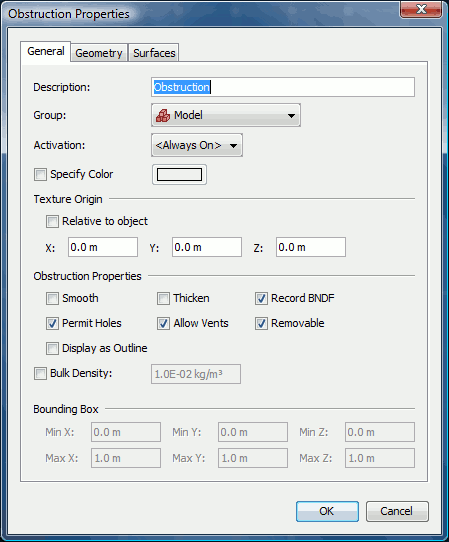

This tab of the obstruction panel presents all options other than those controlling geometry and surface information. This includes activation events (conditions that can cause the obstruction to be added or removed from the simulation) and miscellaneous options such as color and smoothing.

This tab allows you to enter the min and max coordinates of the object. For more elaborate geometry, such as slabs, this tab may contain a table of points and extrusion options. Extrusion is the mechanism PyroSim uses to extend 2-dimensional objects along a vector - creating a 3-dimensional object.

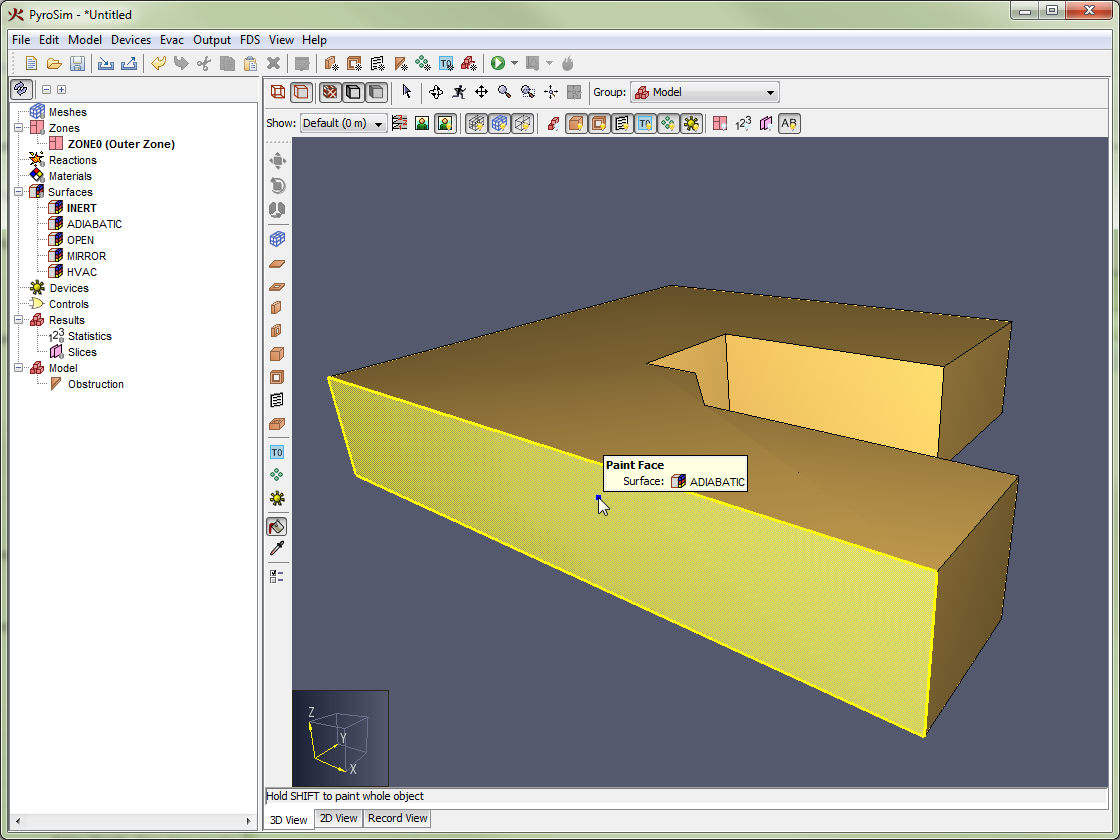

By default, all six sides of an obstruction use the INERT surface. The Surfaces tab can be used to specify one surface to be used for all six sides of the object or assign surfaces on a per-face basis. Alternately, surfaces can be "painted" using the Paint Tool as discussed in Painting Obstructions and Vents.

Holes are used to carve negative spaces out of obstructions. In FDS, holes are similar to obstructions in that they are defined as axis-aligned blocks. Like obstructions in PyroSim, however, holes can be any shape. PyroSim automatically converts them to blocks in the FDS input file.

PyroSim treats holes as first-class objects that can be selected, deleted, and have other operations performed on them like obstructions as discussed in Working with Geometry Objects.

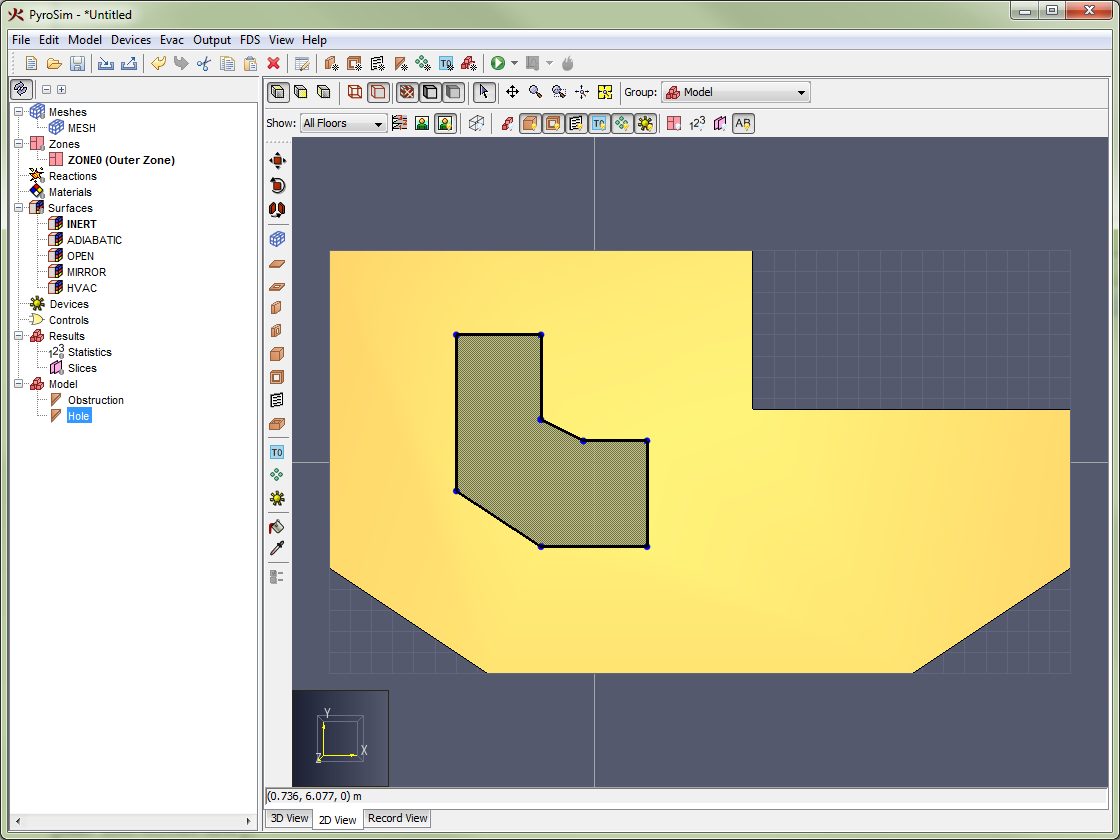

In the 3D and 2D views, holes appear as transparent objects. In addition, for display purposes only, PyroSim carves holes out of obstructions as shown in Figure 40. For complex holes or obstructions or large holes that span many obstructions, this process may be slow. In these cases, hole-cutting display can be turned off by going to the View menu and deselecting Cut Holes From Obstructions.

By default, all obstructions allow holes to be cut from them. To prevent an obstruction from allowing holes, edit the properties of the obstruction as discussed in Obstructions and deselect Permit Holes.

There are various rules that govern how holes are written to the FDS input file. In general, if the PYROGEOM file is enabled, a hole has control logic, and the hole intersects obstructions, the hole will be pre-subtracted from obstructions before the obstructions are converted into blocks, and the holes will be excluded from the FDS file. If the above conditions do not hold, the holes are converted to blocks similarly to obstructions and are written as HOLE records. For more information, see PyroGeom File.

Holes can either be drawn as discussed in Drawing in PyroSim or can be created by opening the Model menu and clicking New Hole.

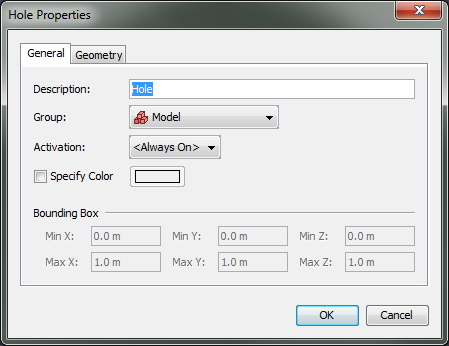

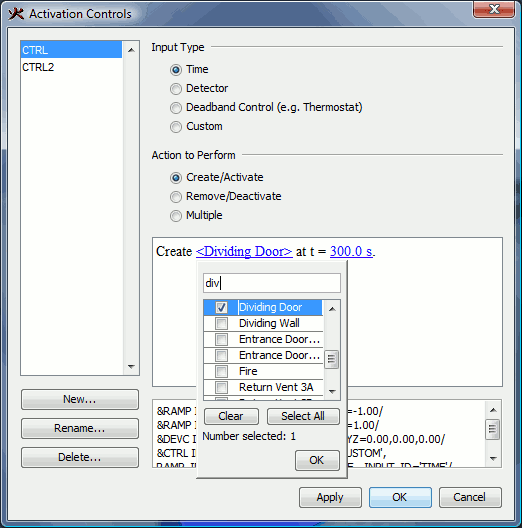

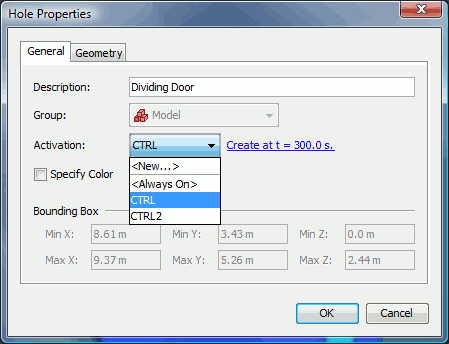

This will open the Hole Properties dialog as shown in Figure 41.

Like obstructions, holes can also be activated as discussed in Control Logic. Holes can also have a color applied.

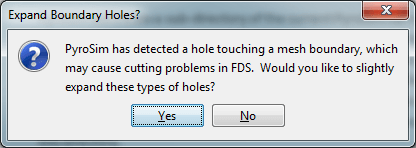

When starting a simulation or exporting an FDS file for some models, the user may receive the following message as shown in Figure 42: "PyroSim has detected a hole touching a mesh boundary, which may cause cutting problems in FDS. Would you like to slightly expand these types of holes?"

FDS currently has an issue where it will not fully cut a hole from an obstruction if both the hole and obstruction touch a mesh boundary at the same location. Instead, FDS leaves a thin obstruction along the mesh boundary. Figure 43 shows a model in PyroSim that can lead this problem. In this model, both the hole and the obstruction touch the bottom of the mesh, and the hole should cut all the way through the mesh. Figure 44 shows this model in FDS where the hole has not been punched all the way through the obstruction.

PyroSim detects potential cases where this might happen and prompts the user with the Expand Boundary Holes dialog. If the user chooses to expand the hole (the Yes option), PyroSim will expand the hole to 1/10 of a mesh cell past the mesh boundary for every side of the hole that touches a mesh boundary. This ensures the hole is properly cut all the way through the obstruction as shown in Figure 45. If the user chooses not to expand these types of holes (the No option), the hole will be written exactly as specified and may lead to the thin obstruction problem.

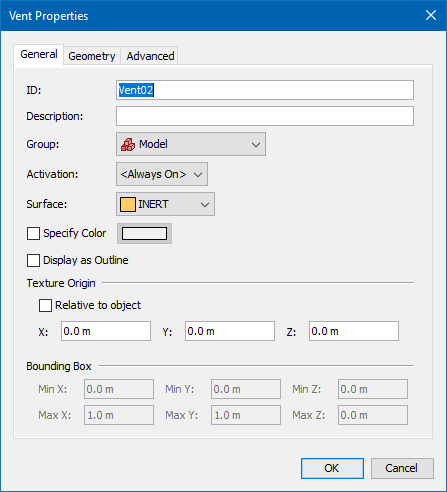

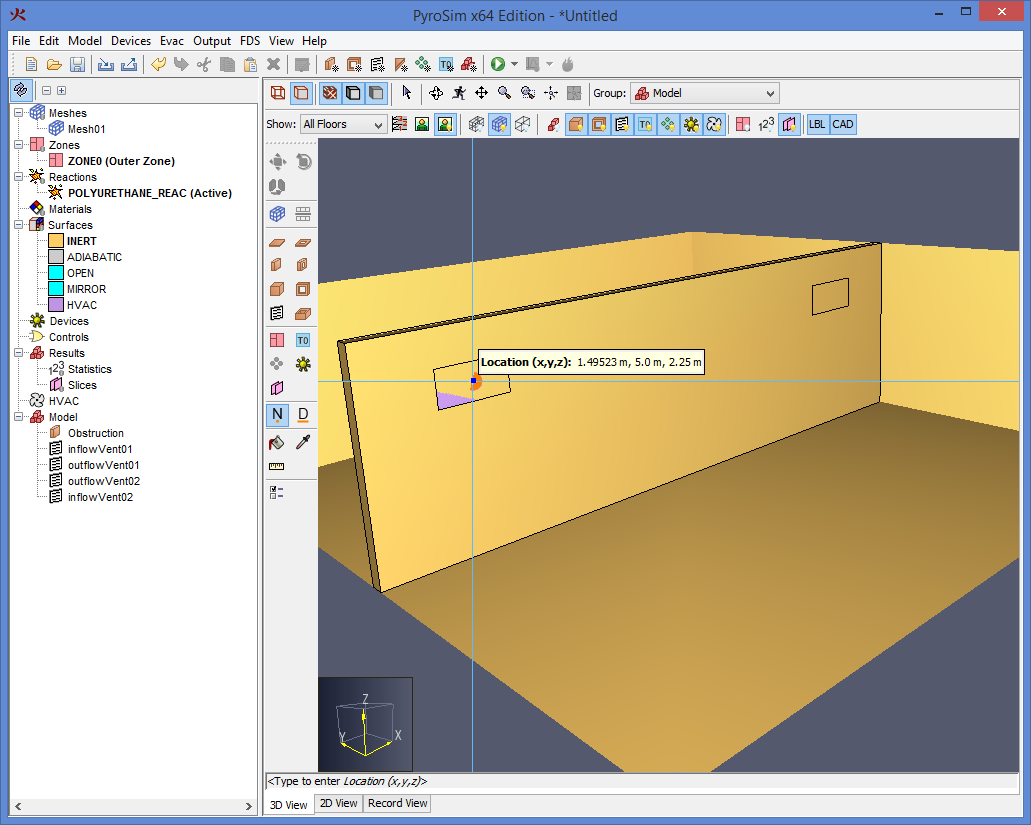

Vents have general usage in FDS to describe a 2D rectangular patch on the surface of a solid obstruction or on a mesh boundary as shown in Figure 46. A vent may have a different surface applied to it than the rest of the obstruction to which it is attached.

Taken literally, a vent can be used to model components of the ventilation system in a building, like a diffuser or a return. In these cases, the vent coordinates form a plane on a solid surface forming the boundary of the duct. No holes need to be created through the solid; it is assumed that air is pushed out of or sucked into duct work within the wall.

You can also use vents as a means of applying a particular boundary condition to a rectangular patch on a solid surface. A fire, for example, is usually created by first generating a solid obstruction and then specifying a vent somewhere on one of the faces of the solid with the characteristics of the thermal and combustion properties of the fuel.

There are two reserved surface types that may be applied to a vent: OPEN and MIRROR. For more information on these types, see Surfaces.

Vents can either be drawn as discussed in Drawing in PyroSim or be created by opening the Model menu and clicking New Vent.

This will open the New Vent dialog as shown in Figure 47. Like obstructions and holes, vents can also be activated, but only if the surface is not MIRROR or OPEN. With the exception of Fire Spread, the other properties are similar to obstructions. Fire Spread can be specified on vents using a burner surface (Surfaces). This option simulates a radially spreading fire at the vent. A vent can also be given radial properties. Defining a Center Point and Radius for a vent will cause FDS to define a vent bounded by the vent’s Bounding Box and the circle generated by the point radius combination.

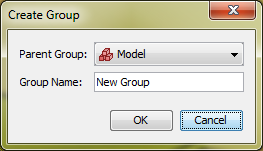

Groups can be used to hierarchically organize the model. Groups can only be seen in the Navigation View. The "Model" is the base group. Users can nest groups inside other groups, allowing the user to work with thousands of objects in an organized way. When the user performs an action on a group, that action will be propagated to all objects in the group.

There are two ways to create a group:

Both of these actions will show the Create Group dialog as shown in Figure 48. This dialog allows the user to choose the parent group and name of the new group.

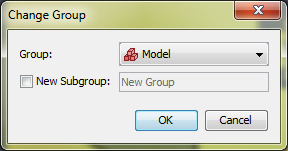

There are several ways to add objects to a group:

In the Change Group dialog shown in Figure 52, select the desired group. If a new group is desired, select New Subgroup and specify a name. If this is chosen, a new group will be created under the specified existing group, and the selected objects will be moved to this new group. * For newly drawn objects, in the 3D or 2D view select the desired group from the group drop-down above the view as shown in Figure 53. All newly drawn objects will be added to this group.

Floors are used in PyroSim to quickly apply clipping filters to the scene to only show a portion of the model. They are also used to initialize the properties of drawing tools so that they draw at the proper Z location.

An example of floor clipping is shown in Floor clipping, where Figure 54 shows all floors and Figure 55 shows a single floor.

To define the floors in a model, go to the 2D or 3D View and click the Define Floor Locations button (![]() ).

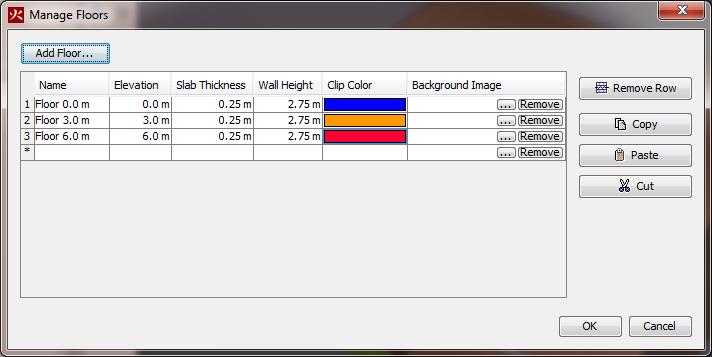

This will display the Manage Floors dialog shown in Figure 56.

).

This will display the Manage Floors dialog shown in Figure 56.

Floors are defined by the following properties:

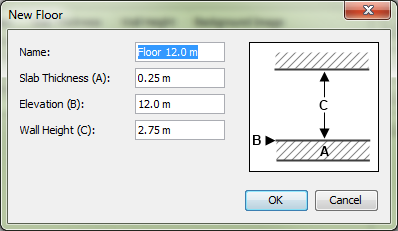

To add a new floor, click the Add Floor. button at the top of the Manage Floors dialog. This will show the New Floor dialog shown in Figure 57. By default this dialog will assume the user wants a floor above the previous floor using that floor’s slab thickness and wall height properties. In this dialog, if the user enters a new slab thickness, the elevation will be automatically updated so the new floor does not overlap the others unless the user enters a specific value for the elevation. In addition, unless the user enters a specific name, a name will be automatically generated based on the elevation.

Press OK to create the new floor.

Press OK again in the Manage Floors dialog to commit the changes.

By default, the model contains one floor at elevation 0.0 m with a slab thickness of .25 m and a wall height of 2.75 m. Using these values leaves a distance of 3.0 m from one floor elevation to another.

Once the floors have been defined, the user can filter the display to show either a single floor or all floors as shown in Figure 7. For most views, the Z clipping range for a particular floor is from the floor elevation minus slab thickness to floor elevation plus wall height. The Z clipping range works differently for the top camera of the 2D view, however. In this view, the clipping is from the elevation of the floor BELOW to the elevation plus wall height of the current floor. This allows the geometry on the floor below to be snapped to in drawing geometry for the current floor. For this to be useful, however, the user may want to use wireframe rendering.

Quickly define floors by selecting some geometry, right-click the selection, and choose the Add Floor to Fit Objects item in the context menu. This will automatically add a floor in the Manage Floors dialog with values based upon the selected geometry.

See Figure 57 for an illustration of the information below.

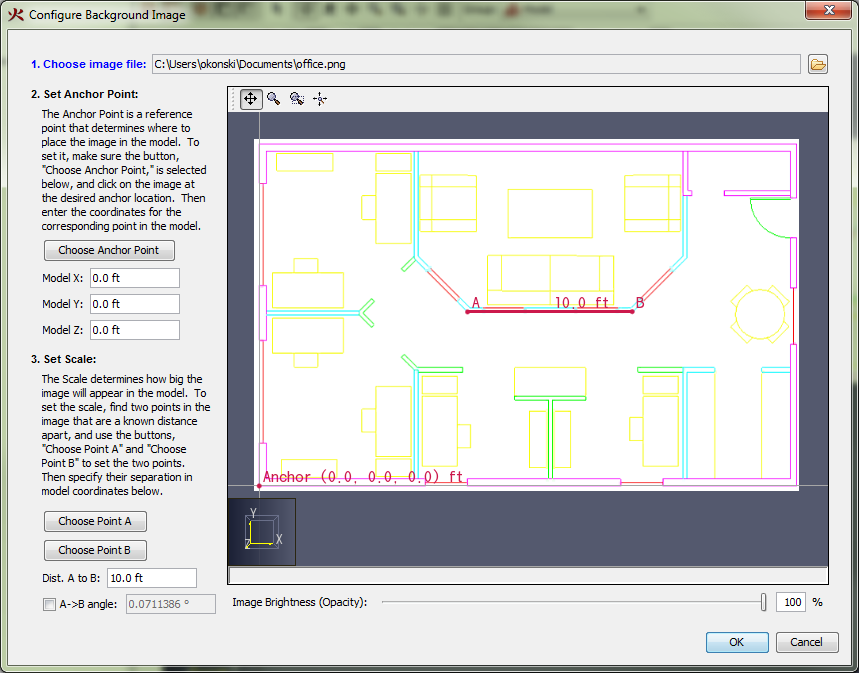

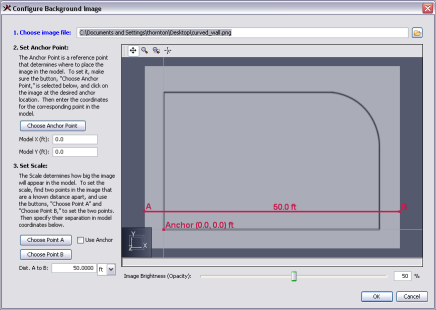

Each floor can have an associated background image.

To add a background image to a floor, go to the 2D or 3D View, select a specific floor, then click the Configure Background Image button (![]() ).

Alternately click the Define Floor Locations button, (

).

Alternately click the Define Floor Locations button, (![]() ), and then in the Background Image column, select the Edit button.

This will display the Configure Background Image dialog shown in Figure 58.

), and then in the Background Image column, select the Edit button.

This will display the Configure Background Image dialog shown in Figure 58.

You will be guided through the following steps:

Now, in the 3D or 2D views, when the user displays a specific floor, the background image for that floor will be displayed.

To turn off the background images, go to the 2D or 3D View, and click the Show Background Images button (![]() ) next to the floors drop-down.

) next to the floors drop-down.

While not a full-fledged drafting application, PyroSim does provide useful drawing features, including the following:

PyroSim provides several drawing and editing tools. These tools are located on the drawing toolbar at the left side of the 3D and 2D Views as shown in Figure 59.

Some of these tools allow a user to create and edit objects such as slabs and walls that are not constrained to the FDS mesh.

In these cases, PyroSim will automatically convert the shapes to mesh-based blocks when the FDS input file is created.

These blocks can be previewed by clicking the Preview FDS Blocks button (![]() ) on the filter toolbar above the 3D or 2D View.

For information on block conversion, see Angled Geometry.

) on the filter toolbar above the 3D or 2D View.

For information on block conversion, see Angled Geometry.

To begin drawing or editing with a tool, the user can single-click the tool from the tool bar. Once the tool has finished drawing/editing its object, the last-used navigation tool is automatically selected.

If the user would like to create several objects with the same tool in succession, the desired tool can be pinned by clicking the tool’s button twice.

The button will show a green dot when pinned (![]() ).

).

Every time the same tool button is clicked, the pinned state of that tool will be toggled, so clicking the button again after pinning will disable pinning (![]() ).

).

At any time, the current drawing/editing tool can be cancelled by pressing ESC on the keyboard. This will also cancel pinning and will revert back to the last-used navigation tool.

Most drawing/editing tools require at least two points to be specified to complete its action, such as drawing the points for a wall or defining the extents of a box.

These tools can operate in two modes:

Each tool has a set of properties that can be modified by clicking the Tool Properties (![]() ) button located at the bottom of the toolbar after selecting the desired tool.

Options such as elevation, height, surface, and color can all be edited in the Tool Properties dialog.

) button located at the bottom of the toolbar after selecting the desired tool.

Options such as elevation, height, surface, and color can all be edited in the Tool Properties dialog.

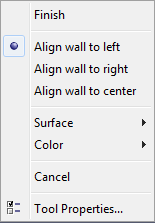

In addition to the tool properties, each tool also has additional quick actions. To show these actions, start the desired tool and then right-click in the 2D or 3D View. This opens a context menu with the quick actions. Figure 60 shows an example of the quick action menu for the wall tool.

This menu allows the user to perform actions specific to the tool, such as closing a polygon, picking a surface, setting wall alignment, accessing the tool properties, etc.

Snapping is one way to precisely draw and edit objects. It is the process of finding some element in the scene, such as a vertex or edge close to the cursor, and snapping the cursor to that element like a magnet.

In PyroSim, snapping can be performed against the solution meshes, objects in the model, and orthographic constraints. The 2D View additionally provides a sketch grid and polar (angle) constraints. If a snap point is found, an indicator dot shown in Figure 61 will appear at the snap point.

By default, snapping is enabled. It can be disabled by holding ALT on the keyboard while using a drawing/editing tool.

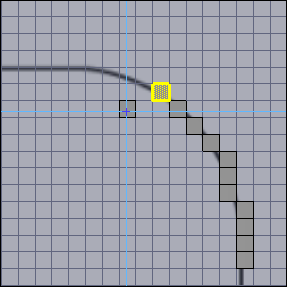

If there are any solution meshes in the model (see Meshes), PyroSim can snap to them during drawing and editing. For each mesh that is visible, PyroSim can snap to its boundary edges, boundary faces, grid lines, and the intersections of the grid lines, depending on which mesh display filters are active as discussed in Filtering.

PyroSim also provides a user-defined drawing grid, or sketch grid, in the 2D View as shown in Figure 62.

When a new model is created, the sketch grid is visible and can be snapped to in the 2D view. The default spacing for the divisions is 1 m, but can be changed by going to the View menu and clicking Set Sketch Grid Spacing.

Once the user has created a solution mesh, PyroSim will automatically switch to solution mesh snapping and disable sketch grid snapping. In the 2D View, PyroSim will only snap to the sketch grid or visible solution meshes. To switch which snapping is being used, on the View menu choose Snap to Sketch Grid or Snap to Model Grids. To disable grid snapping altogether, on the View menu choose Disable Grid Snapping.

All objects displayed in the model can be snapped to when using the drawing/editing tools. There are three basic categories of geometry that can be snapped to on objects: faces, edges, and vertices. Objects can have any combination of types. If there are multiple types close to the cursor, PyroSim will give vertices precedence over edges and edges precedence over faces.

Constraints are dynamic snapping lines that are only visible when the cursor is near them. They appear as infinite dotted lines as shown in Figure 63.

PyroSim contains two types of constraints:

If a constraint is currently being snapped to, that constraint can be locked by holding SHIFT on the keyboard. While holding SHIFT, a second dotted line will extend from the cursor to the locked constraint (the first dotted line). This is useful for lining up objects along a constraint with other objects.

For instance, in Figure 64, a box already exists in the model. A second slab is being drawn such that the third point of the slab lines up with the right side of the first box. This was done as follows:

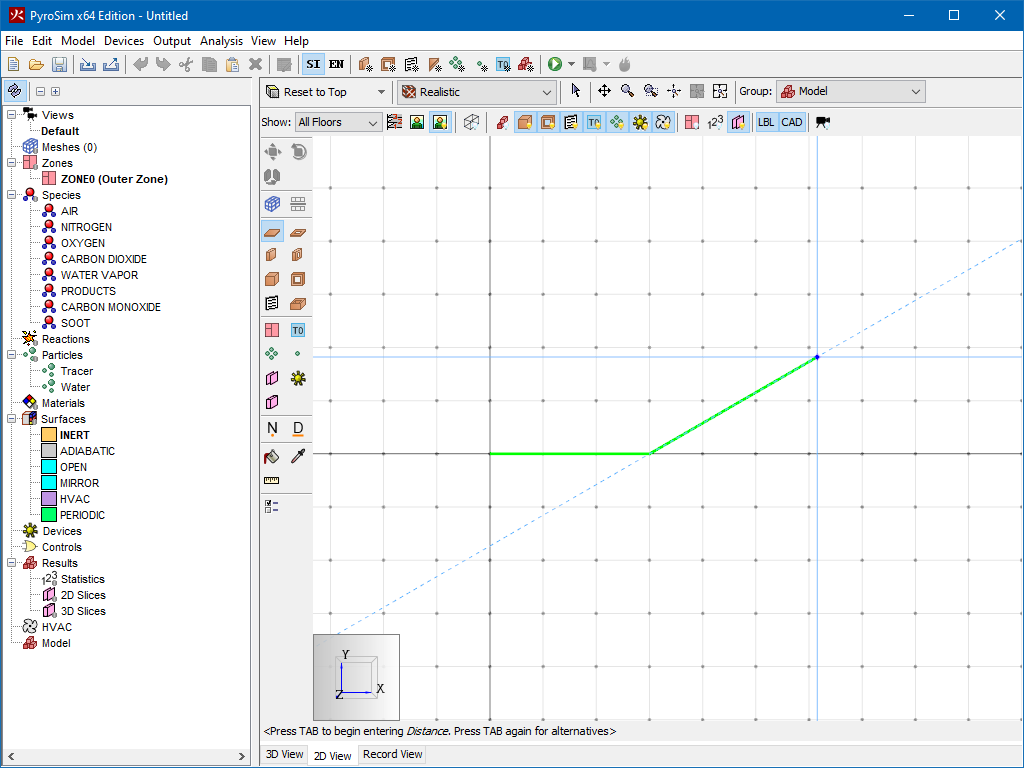

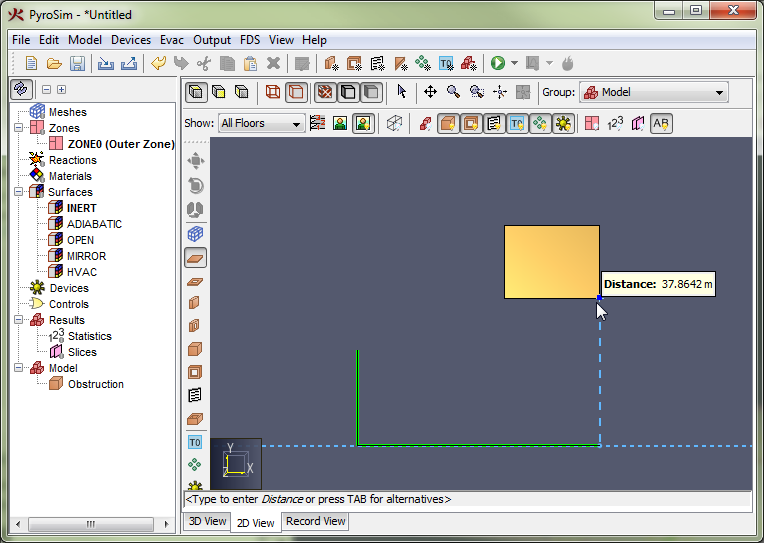

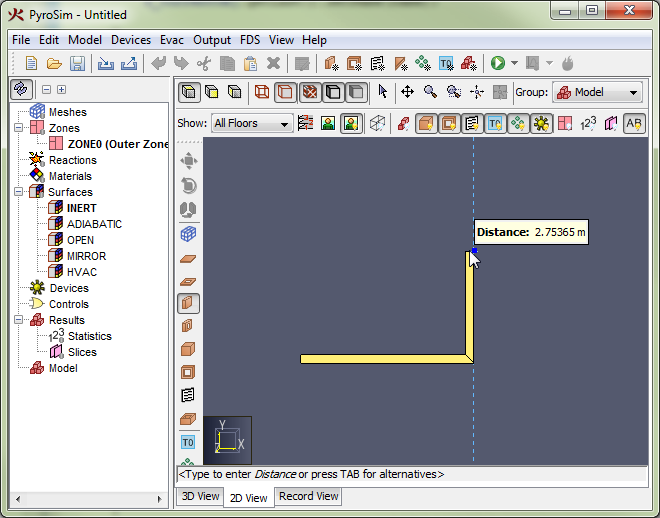

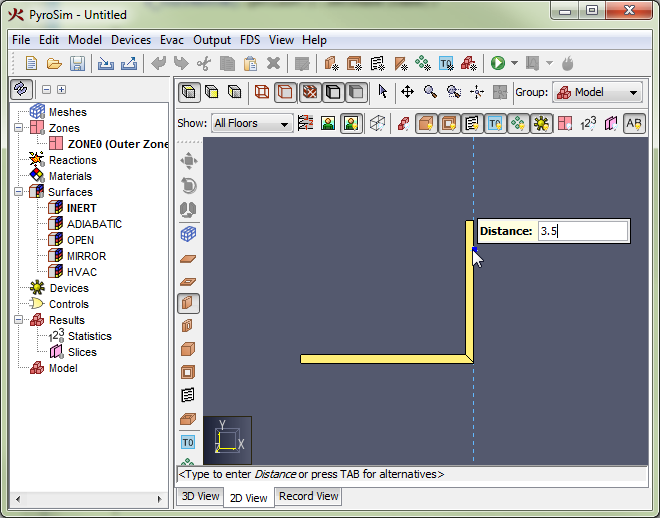

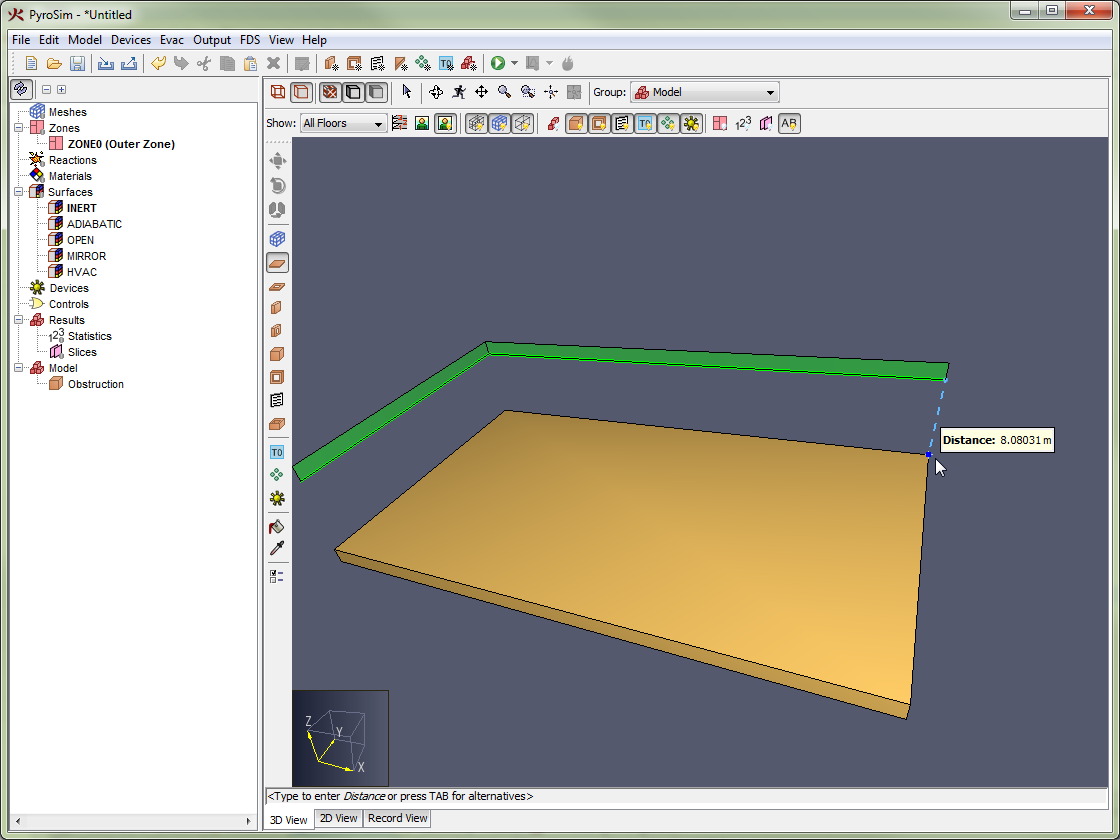

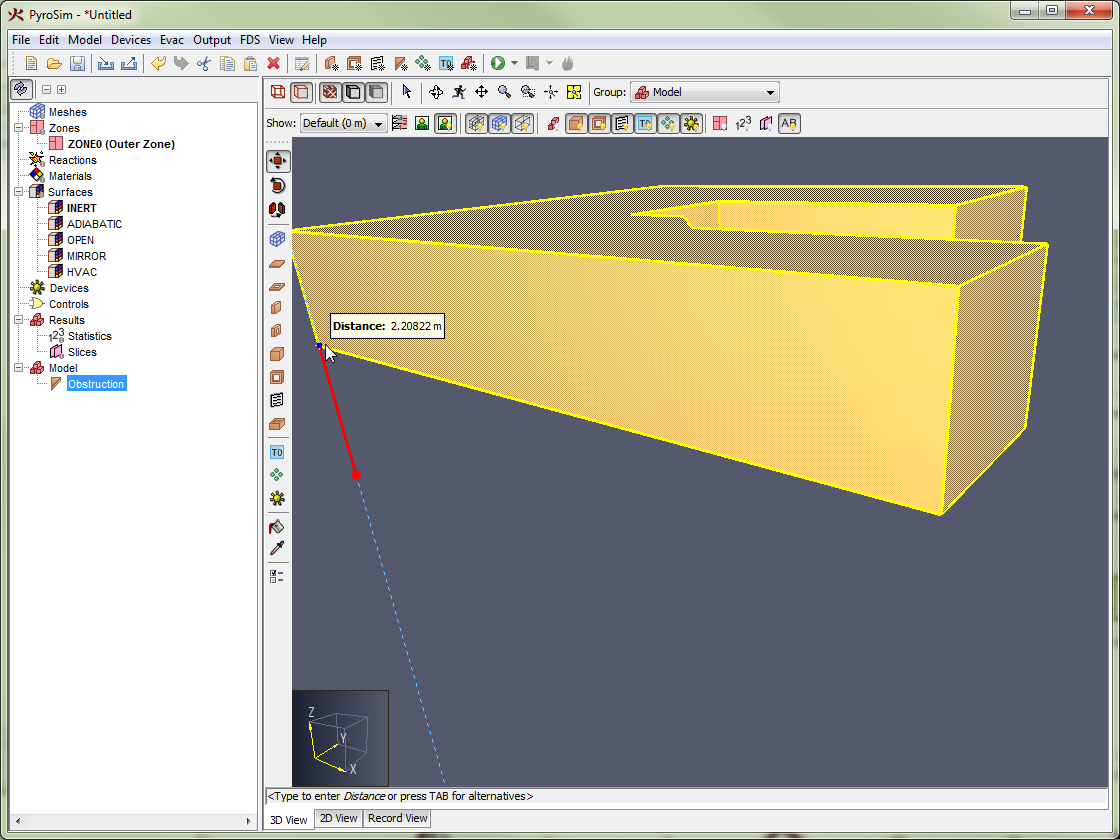

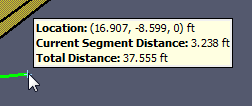

While using a drawing/editing tool, a popup window may appear next to the cursor, such as in Figure 65. This window shows the value used to determine the next point or value for the current tool. In this figure the value is the Distance from the previous point along the vector from the previous point to the current cursor location. For other tools, this value may be angle or relative offset, etc.

The value is editable if the status bar at the bottom of the 3D or 2D View indicates it is. For instance, in the figure, the status bar says "<Type to enter Distance or press TAB for alternatives>". If the user starts typing, the popup window will be replaced with an editing window as shown in Figure 66. If the user presses ENTER, the typed value will be committed. If the user presses ESC instead, the keyboard entry will be cancelled.

Pressing TAB cycles through alternate input methods to determine the next value. For instance, pressing TAB with the wall tool allows the user to enter a relative offset from the last point instead of a distance. Pressing TAB a second time allows the user to enter an absolute position for the next point, and pressing TAB a third time will cycle back to the distance input.

Precise keyboard entry may be easiest for some users when using the multi-click mode of drawing rather than using the click-drag mode. Using multi-click allows both hands to be used to type as opposed to click-drag, which requires one hand to remain on the mouse.

There are some key differences between drawing in the 2D and 3D Views. The 2D View is useful when drawing should be restricted to one pre-defined plane. It is also useful for lining up objects along the X, Y, or Z axes. The 3D View is useful when an object such as a vent or solid-phase device needs to be snapped to the face of an obstruction or vent or if the user would like to build objects by stacking them on top of one another.

When drawing in the 2D View, the drawing will always take place in the drawing plane specified in the tool properties, and snapping is only performed in the local X and Y dimensions. The local Z value will remain true to the drawing plane. In addition, if a tool has some sort of height or depth property, the tool will also remain true to that value. Slabs in different planes aligned in the 2D View shows two slabs that have been drawn in the top view (Figure 67), one at Z = 0 m and the other at Z = 1.5 m. While snapping was used to partially align the objects, they both remain in the Z planes specified in their tool properties shown in the rotated view (Figure 68).

The 3D View uses snapping in all three dimensions, causing tool properties to be interpreted more loosely. The drawing plane and depth properties for a drawn object are context-sensitive in the 3D View. When using tools such as the slab tool, the first clicked point determines the drawing plane. If, on this first click, another object is snapped to, the drawing plane is set at the Z location of that snap point. The tool properties' drawing plane is only used if nothing is snapped to on the first click.

This 3D snapping feature of the 3D View is useful for drawing vents on obstructions and attaching solid-phase devices to obstructions as shown in Figure 69.

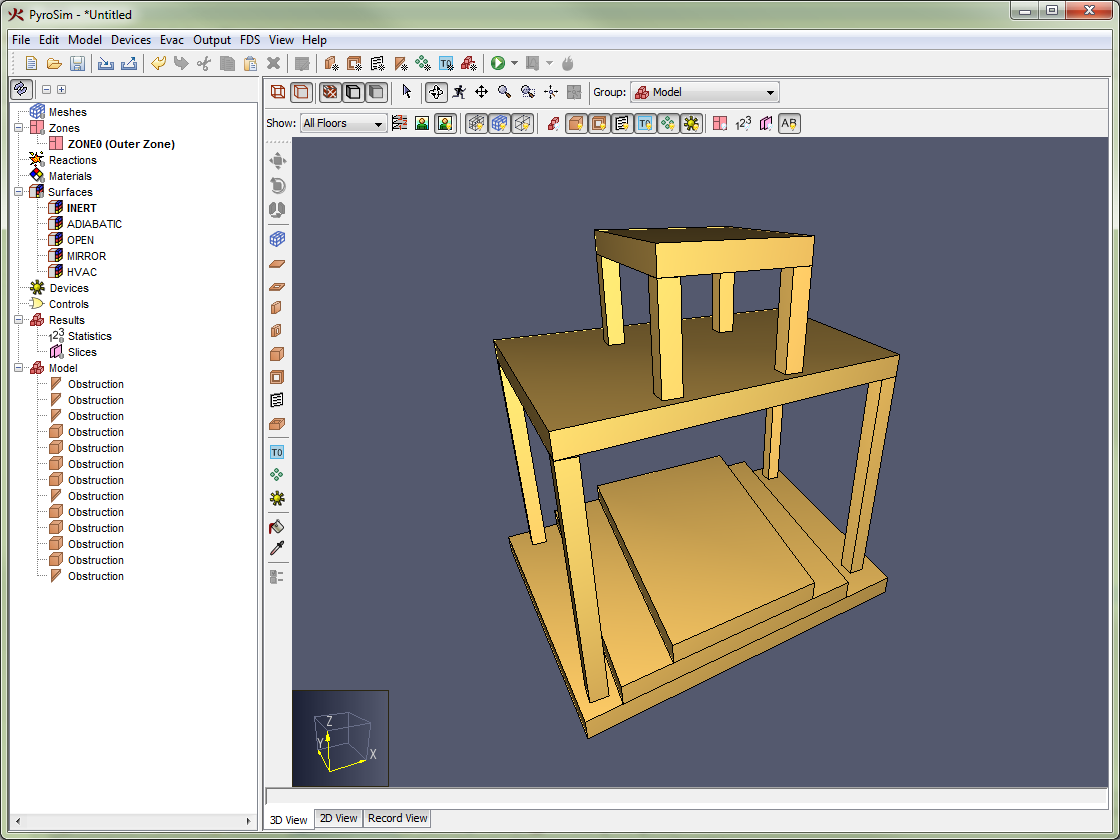

The 3D snapping feature is also useful for stacking objects, as shown in Figure 70. In this figure, the drawing plane was never changed. All the objects were stacked on top of each other using snapping.

While stacking can be useful for obstructions, a user must be more careful when drawing holes in the 3D View. For instance, with the slab hole tool and block hole tool, the user will need to change the extrusion direction to properly direct the hole into the obstruction.

For instance, if the user draws a slab obstruction in the 3D View and then draws a slab hole while snapping to the obstruction, the hole will be stacked on top of the obstruction without cutting a hole as shown in Figure 71.

To draw this properly, the user would need to change the extrusion direction when drawing the hole by pressing CTRL on the keyboard or changing it through the tool’s right-click menu. This will result in a proper hole as shown in Figure 72.

This is not a problem in the 2D View since it always uses the drawing plane set in the tool properties instead of stacking the objects.

Once the drawing plane for a tool has been established by the first click, the tool can still determine the next points by snapping to objects in another plane. In this case, the snapped points will be projected to the drawing plane for the current tool. A dotted line will show how the snapped point was projected to the plane. For instance, Figure 73 shows a new slab being drawn in the Z = 1.5 plane. A slab below the new slab is being snapped to determine the new slab’s points.

There are four tools that can draw obstructions, for more information on obstructions, see Obstructions.

![]() Slab Obstruction Tool: Used to draw the slab for a floor.

Slab Obstruction Tool: Used to draw the slab for a floor.

![]() Wall Obstruction Tool: Used to draw a wall.

Wall Obstruction Tool: Used to draw a wall.

![]() Block Obstruction Tool: Used to fill grid cells with obstructions.

Block Obstruction Tool: Used to fill grid cells with obstructions.

![]() Room Tool: Used to draw a rectangular room

Room Tool: Used to draw a rectangular room

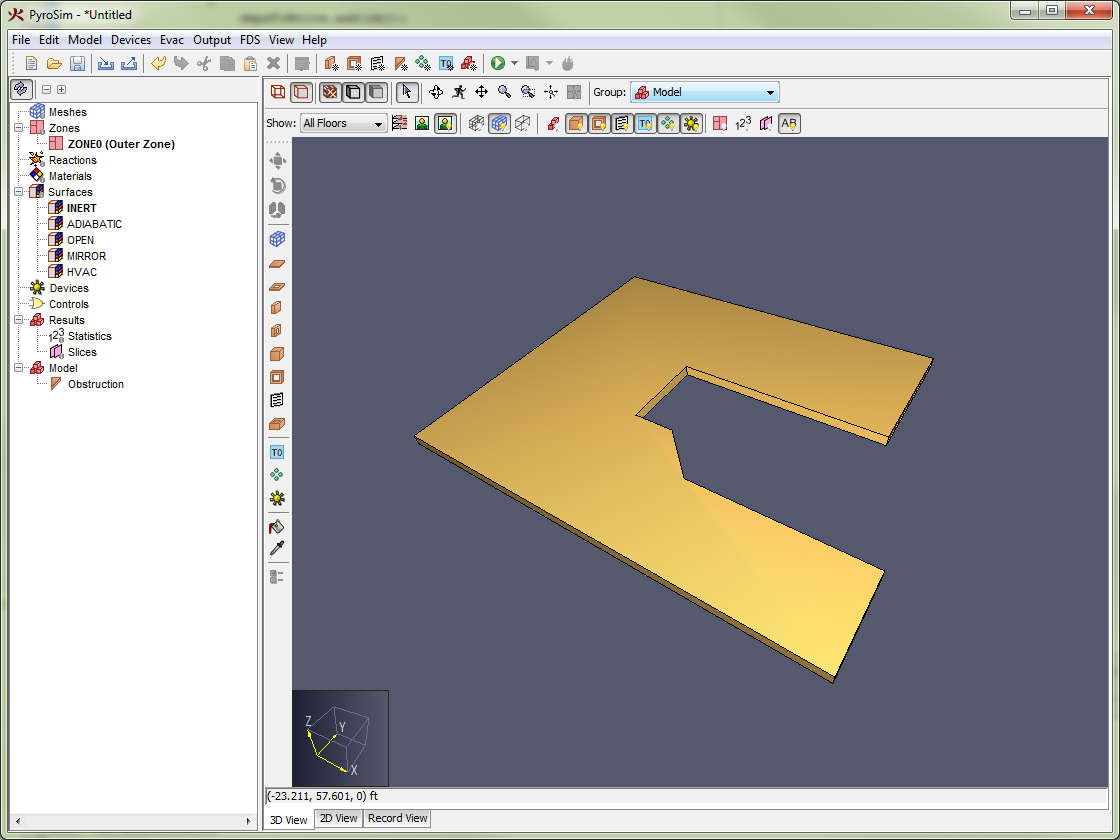

For all the obstruction tools, the tool properties dialog (![]() ) will appear similar to that in Figure 74.

The only section of the dialog that will change between these tools is the geometry, such as Z Location and Thickness.

All other properties, including name, surface, color, and obstruction flags appear in all obstruction dialogs.

These parameters control the properties that will be applied to the next drawn obstruction.

) will appear similar to that in Figure 74.

The only section of the dialog that will change between these tools is the geometry, such as Z Location and Thickness.

All other properties, including name, surface, color, and obstruction flags appear in all obstruction dialogs.

These parameters control the properties that will be applied to the next drawn obstruction.

The surface and color of the next obstruction can also be set via the right-click menu for the tool.

A slab is an extruded polygonal object as shown in Figure 75 that can be used to draw the slab for a floor in a building.

The slab obstruction tool ![]() adds two additional properties to the tool dialog for obstructions:

adds two additional properties to the tool dialog for obstructions:

To draw the polygon vertices of the slab obstruction, perform the following:

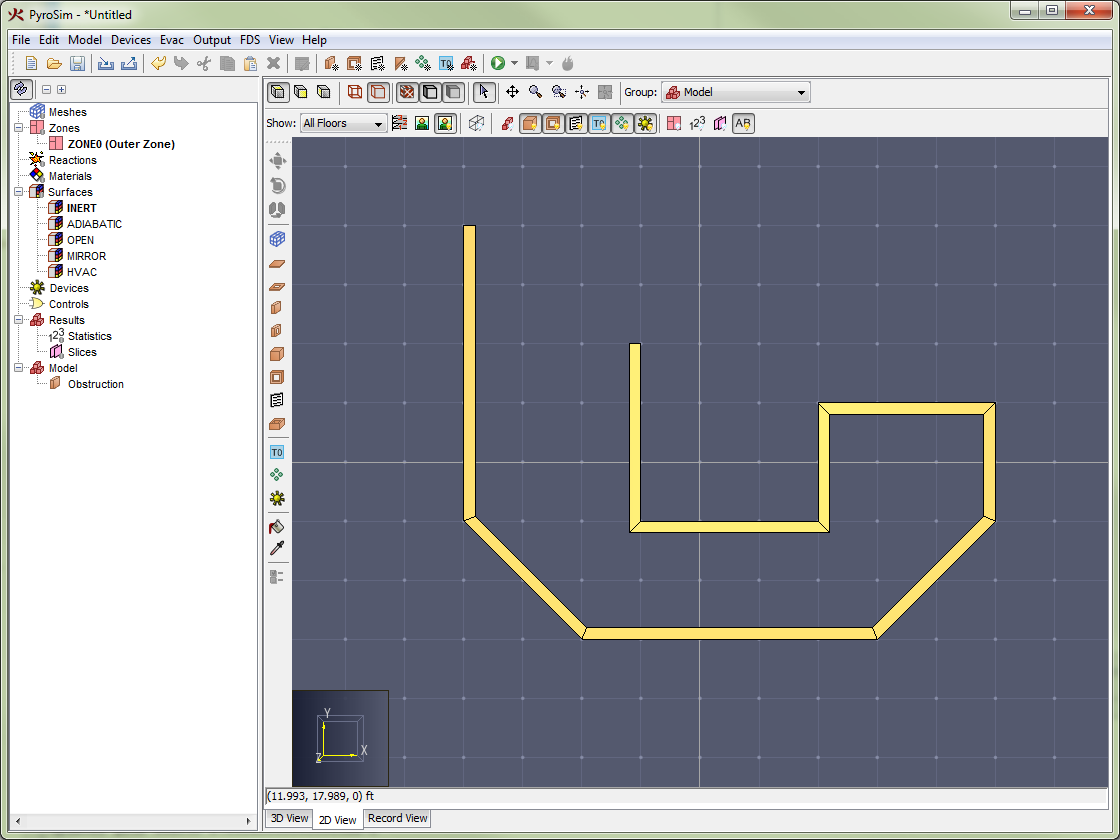

The wall obstruction tool (![]() ) can be used to draw multi-segmented walls as shown in Figure 76.

In this figure, there is only one wall.

The user specifies a path along the floor from which the wall is extruded up.

The wall can be aligned to the left, right, or center of the drawn path.

) can be used to draw multi-segmented walls as shown in Figure 76.

In this figure, there is only one wall.

The user specifies a path along the floor from which the wall is extruded up.

The wall can be aligned to the left, right, or center of the drawn path.

The wall obstruction tool adds three properties to the tool properties dialog:

The alignment of the wall can be controlled through the right-click menu for the tool or can be cycled by pressing the CTRL key on the keyboard. The alignment options are Left (Figure 77), Center (Figure 78) and Right (Figure 79) as shown in Wall alignment options.

To draw a wall, perform the following steps:

If the first clicked point is clicked again after drawing at least two segments or Close is chosen from the right-click menu, the tool will draw one last segment from the last clicked point to the first point and finish. Alternately, the wall can be ended at the last clicked point by choosing Finish from the right-click menu.

The Block Obstruction Tool (![]() ) can be used to quickly fill grid cells with blocks as shown in Figure 80 or place a block with a single click.

) can be used to quickly fill grid cells with blocks as shown in Figure 80 or place a block with a single click.

This tool adds the following properties to the tool properties dialog:

In addition, the extrusion direction for the block can be toggled by pressing CTRL on the keyboard or through the right-click menu for the tool.

To create blocks using this tool, perform the following:

The Room Tool (![]() ) can be used to draw a rectangular room using one closed wall as shown in Figure 81.

) can be used to draw a rectangular room using one closed wall as shown in Figure 81.

The room tool contains the same properties as the wall obstruction tool.

To draw a room with the room tool perform the following:

There are three tools that can draw holes, for more information on holes, see Holes.

![]() Slab Hole Tool: Used to draw a hole in a floor slab.

Slab Hole Tool: Used to draw a hole in a floor slab.

![]() Wall Hole Tool: Used to draw an opening in a wall, such as for a doorway or window.

Wall Hole Tool: Used to draw an opening in a wall, such as for a doorway or window.

![]() Block Hole Tool: Used to fill grid cells with holes.

Block Hole Tool: Used to fill grid cells with holes.

All these tools work the same as their obstruction counterparts, but they do not have the properties specific to obstructions, such as the surface or obstruction flags.

There is only one tool for drawing vents (for more information on vents, see Vents). PyroSim only allows vents in an X, Y, or Z plane. Vents cannot currently be drawn off-axis like walls can.

Vents also must be attached to solid obstructions (at least one grid cell thick). This is easily accomplished by drawing the vent in the 3D View (see 2D versus 3D Drawing).

To draw a vent, perform the following:

Solution meshes can also be drawn in PyroSim with the Solution Mesh Tool (![]() ) as shown in Figure 82.

) as shown in Figure 82.

The solution mesh tool has the following tool properties:

To draw a solution mesh, perform the following:

Solution meshes can be easily split into two or more sub-meshes by using the Mesh Splitter Tool (![]() ).

).

To split one or more meshes, perform the following:

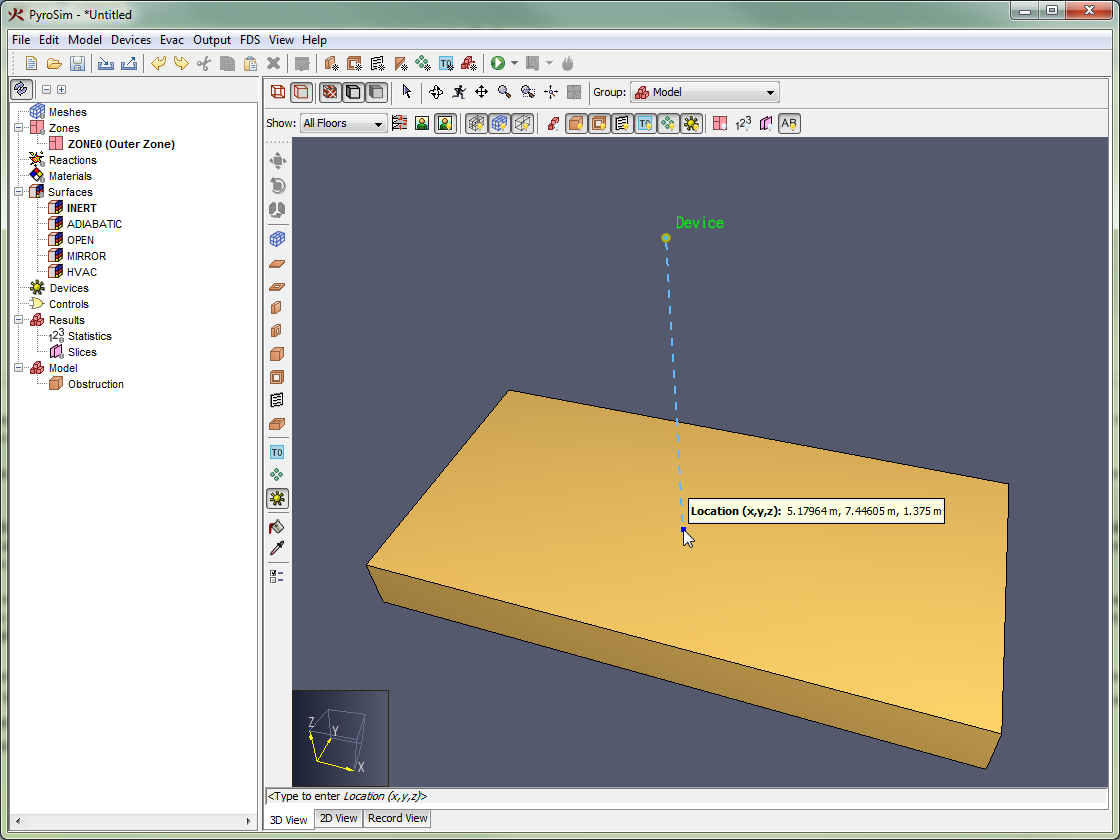

PyroSim allows point devices to be drawn with the Device Tool (![]() ), for more information on devices, Devices.

), for more information on devices, Devices.

The device tool has the following properties:

To draw a device, perform the following:

If it is a solid-phase device, the device’s location will snap directly to the point under the cursor if one is found. This makes it trivial to attach a solid-phase device to an obstruction. If the device is a gas-phase device, however, the device’s location will be projected to the plane as set in the device tool properties as shown in Figure 86. This makes it easy to draw devices at a specific height above the floor. This behavior can be overridden for either type of device by selecting Lock Z to [V] (where V is the drawing plane) or Lock Z to Snap Location in the tool’s right-click menu. Lock Z to [V] is the automatic behavior for gas-phase devices and Lock Z to Snap Location is the automatic behavior for solid-phase devices.

Planar slices, as discussed in 2D Slices can be drawn with the planar slice tool (![]() ).

).

To do so, perform the following:

The slice plane can be changed through the right-click menu, by click-dragging the left mouse button, or by pressing CTRL on the keyboard to cycle through the options.

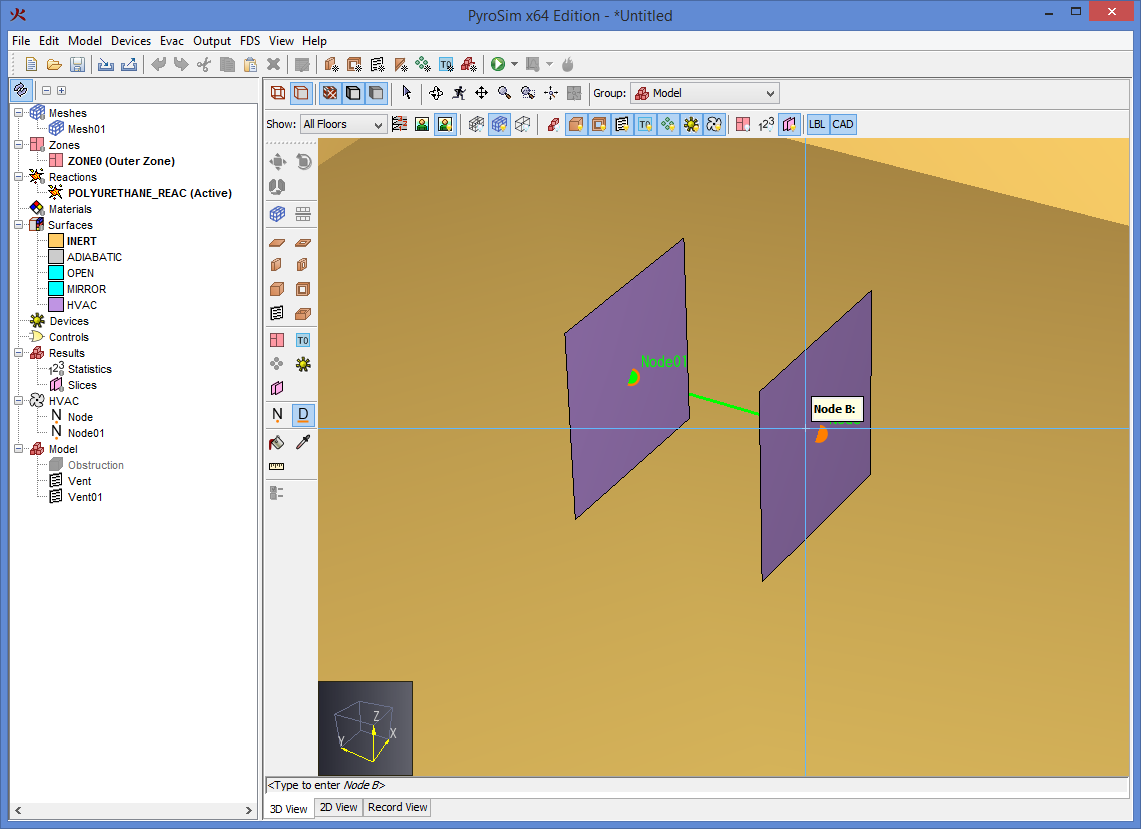

HVAC nodes as discussed in HVAC Node, can be drawn with the HVAC Node Tool (![]() ).

).

To do so, perform the following:

PyroSim allows HVAC ducts to be drawn with the HVAC Duct Tool (![]() ).

).

To do so, perform the following:

PyroSim can also be used to draw:

![]() Init Regions (Init Regions) with the Init Region Tool.

Init Regions (Init Regions) with the Init Region Tool.

![]() Particle Clouds (Particle Clouds) with the Particle Cloud Tool.

Particle Clouds (Particle Clouds) with the Particle Cloud Tool.

![]() Single Particles (Particles) with the Particles at a Point Tool.

Single Particles (Particles) with the Particles at a Point Tool.

![]() 3D Slices (3D Slices) with the 3D Slices tool.

3D Slices (3D Slices) with the 3D Slices tool.

![]() Pressure Zones with the with the Zone Tool.

Pressure Zones with the with the Zone Tool.

These tools draw axis-aligned boxes, and so they behave similarly. They all have the following drawing properties:

To draw one of these objects, perform the following:

Nearly all geometric objects can also be graphically edited in the 3D or 2D View with the Select/Manipulate Tool (![]() ).

).

Editing is performed through an object’s editing handles. Handles appear on an object either as a blue dot as shown in Figure 90 or a face with a different color. The dots indicate a point that can be moved in either two or three dimensions. A discolored face indicates that a face can be moved or extruded along a line.

To graphically edit an object, perform the following:

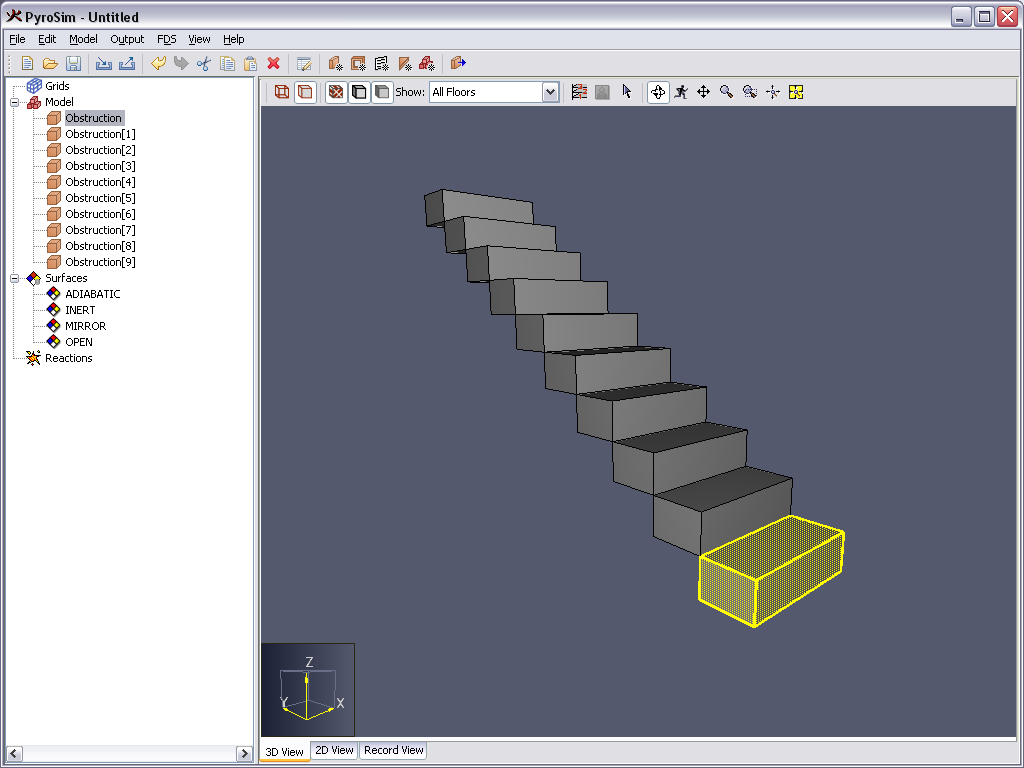

PyroSim provides a variety of tools to transform geometry objects. With the transform tools, users can move, rotate, and mirror objects.

Each tool has an alternate mode to copy the source objects with the transform. To toggle copy mode on/off, press the CTRL key on the keyboard. Alternately, choose Copy Mode or Move Mode from the tool’s right-click menu. When using copy mode, the selected objects are copied and the copies are transformed.

This tool allows the user to move selected objects to a new location as shown in Figure 92.

To use this tool, perform the following:

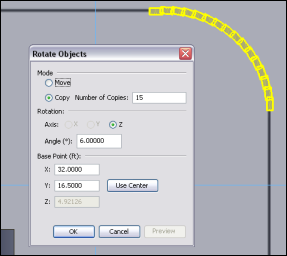

This tool allows the user to rotate selected objects as shown in Rotating an object with the Rotate Tool.

To use this tool, perform the following:

The selected objects will be rotated by the angle between the reference and angle vectors.

The following defines the axis about which objects are rotated for each view:

The mirror tool allows objects to be mirrored across a plane as shown in Mirroring an object using the Mirror Tool below.

To use the mirror tool, perform the following: